The PosiTector UTG® measures the wall thickness of materials such as steel, plastic and more using ultrasonic technology. Ideal for measuring the effects of corrosion or erosion on tanks, pipes or any structure where access is limited to one side. Multiple echo (UTG-ME) Thru-Paint models measure the metal thickness of a painted structure without having to remove the coating.

Available with corrosion probe or multiple-echo probe

Available with corrosion probe or multiple-echo probe

Includes

- NIST-Traceable Calibration Certificate

- 2-Year Warranty (body and probe)

- Made in USA

- Large, easy-to-read, graphics LCD with multilingual support

- Enhanced one-handed menu navigation

- Pre-programmed velocities - simply select from a list of common materials or enter your own with ease

- Smart Couple™ - eliminates inadvertent decoupling- ideal for analyzing large areas using multiple passes

- Flashing display - ideal for noisy environment

- RESET feature instantly restores factory settings

Durable

- Solvent, acid, oil, water and dust resistant - weatherproof

- Impact resistant lens

- Wear-resistant probe tip

- Shock-absorbing, protective rubber holster with belt clip

- Two (2) year warranty on both body and sensors

Accurate

- Precision ultrasonic transducers provide fast, accurate readings

- Certificate of Calibration (Long Form) showing traceability to NIST included

- Conforms to national and international standards including ASTM E797

- Built-in temperature compensation ensures measurement accuracy

Versatile

- Gauge body accepts all PosiTector UTG (wall thickness), SPG (surface profile), DPM (environmental) and 6000 (coating thickness) probes

- Hi Contrast backlit display for bright or dark environments

- Single or two point adjustment

- Inch/mm switchable

- Display Languages: English, French, German, Spanish, Japanese, Chinese, Korean, Dutch, Portuguese, Italian, Norwegian, Russian, Czech, Polish and Turkish.

- Flip display enables right-side-up viewing

- Uses alkaline or rechargeable batteries (built-in charger)

Powerful

- Min Scan - measurement rate of up to 20 readings per second with onscreen min and max for quick inspection over a large area

- Statistics - continually displays/updates average, standard deviation, min/max thickness and number of thickness readings

- HiLo alarm audibly and visibly alerts when measurements exceed user-specified limits

- Every stored measurement is date and time stamped

- Software updates via web keep your gage current

- Multiple measurement download/transfer options:

- USB port for fast, simple connection to a PC and to supply continuous power. USB cable included

- USB mass storage - stored readings and graphs can be accessed using universal PC/ Mac web browsers or file explorers. No software required

- PosiTector.net - a free web-based application offering secure storage of thickness readings

- PosiSoft Software Compatible - Continue using the familiar legacy software you have used for years. Available as a free download.

- Screen Capture -record and save image into USB flash memory for record keeping and review

Step 1: Select a body

(Standard or Advanced features)| Feature Comparison Chart | Basic (1) | Memory (3) |

|---|---|---|

| Hi Contrast LCD Display |  Color |

Color |

| Reading Storage Capacity | 250 in one group | 100,000 in up to 1000 groups |

| Statistics - Instantly calculate average, standard deviation, min/max thickness and number of readings while measuring | ||

| Hi-Lo limits audibly and visibly alerts when measurements exceed your specified limits | ||

| Min Scan - measurement rate of up to 20 readings per second with on-screen min and max for quick inspection over a large area | ||

| A Scan - with adjustable Gain with screen capture for further analysis and documentation | - | |

| B Scan - display in which a cross sectional profile of the test material is represented | - | |

| Batch Annotation - Create meaningful batch names and enter notes directly on the instrument using a familiar on-screen QWERTY keyboard. | - | |

| Bluetooth Wireless Technology for data transfer to a PC or optional portable printer | - | |

| Onscreen help, real time graphing, picture prompting and batch notes | - |

Step 2: Select Probe Style

Corrosion Probe Measures the wall thickness of materials such as steel, plastic and more. Ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side

Measures the wall thickness of materials such as steel, plastic and more. Ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side

- 5 MHz dual element transducer with wear resistant PEEK probe tip

- Automatic V-Path compensation for thin materials

- NEW UTG CX Xtreme probe with braided stainless steel cable and heavy-duty strain reliefs for demanding applications

Multiple-Echo Probe

Features Thru-Paint capability to quickly and accurately measure the metal thickness of a painted structure without having to remove the coating. The most accurate method to measure the remaining wall thickness of a painted structure because it automatically disregards the coating, lowering inspection time and expense. Also ideal for measuring on sandblasted materials or other applications requiring a durable wear face.

Features Thru-Paint capability to quickly and accurately measure the metal thickness of a painted structure without having to remove the coating. The most accurate method to measure the remaining wall thickness of a painted structure because it automatically disregards the coating, lowering inspection time and expense. Also ideal for measuring on sandblasted materials or other applications requiring a durable wear face.

Features Thru-Paint capability to quickly and accurately measure the metal thickness of a painted structure without having to remove the coating. The most accurate method to measure the remaining wall thickness of a painted structure because it automatically disregards the coating, lowering inspection time and expense. Also ideal for measuring on sandblasted materials or other applications requiring a durable wear face.

Features Thru-Paint capability to quickly and accurately measure the metal thickness of a painted structure without having to remove the coating. The most accurate method to measure the remaining wall thickness of a painted structure because it automatically disregards the coating, lowering inspection time and expense. Also ideal for measuring on sandblasted materials or other applications requiring a durable wear face.

- 5MHz contact probe with wear resistant Alumina probe tip

- Multiple Echo technique averages 3 or more echoes for accurate and reliable readings

- Most accurate method to measure remaining wall thickness of a painted structure because it automatically disregards the coating, lowering inspection time and expense.

- Toggle easily between:

- Multiple Echo mode to eliminate coating thickness

- Single Echo mode to detect pits and flaws, and to increase the measurement range

The new PosiTector® UTG CX Xtreme corrosion probe features the same trusted and precise ultrasonic technology as the PosiTector UTG C probe with the addition of a robust braided stainless steel cable and heavy-duty strain reliefs. It is the direct result of inspectors’ requests for a probe that features the same accuracy and ease-of-use of the current PosiTector UTG C with additional ruggedness to handle even more demanding applications.

The new PosiTector® UTG CX Xtreme corrosion probe features the same trusted and precise ultrasonic technology as the PosiTector UTG C probe with the addition of a robust braided stainless steel cable and heavy-duty strain reliefs. It is the direct result of inspectors’ requests for a probe that features the same accuracy and ease-of-use of the current PosiTector UTG C with additional ruggedness to handle even more demanding applications.

PosiTector UTG C & UTG CX Features:

- Braided stainless steel cable and heavy-duty strain reliefs for demanding applications (PosiTector UTG CX only)

- 5 MHz dual element transducer with durable PEEK probe tip

- Automatic V-Path compensation for thin materials

- Pre-programmed velocities: Simply select from a list of common materials or enter your own

- Min Scan: Measurement rate of up to 20 readings per second with onscreen min and max for quick inspection over a large area

- Conforms to ASTM E797

| Corrosion (UTG-C) | Xtreme Corrosion (UTG-CX) | Multiple Echo (UTG-ME) | |

|---|---|---|---|

| Probe Type | 5 MHz dual element | 5 MHz dual element | 5 MHz contact |

| Thru-Paint Capability (Multiple Echo) |

No | No | Yes |

| Measurement Range* (Single Echo) |

0.040" to 5.000" 1.00 to 125.00 mm |

0.040" to 5.000" 1.00 to 125.00 mm |

0.100" to 5.000" 2.50 to 125.00 mm |

| Measurement Range* (Multiple Echo) | N/A | N/A | 0.100" to 2.500" 2.50 to 60.00 mm |

| Accuracy | ±0.001" / ±0.03 mm | ±0.001" / ±0.03 mm | ±0.001" / ±0.03 mm |

| Material Surface Temp | -40° to +150° C (-40° to +300° F) | -40° to +150° C (-40° to +300° F) | -40° to +150° C (-40° to +300° F) |

| Material (Menu Option) | Longitudinal Velocity | Min Range* | Max Range* | |||

|---|---|---|---|---|---|---|

| in/us | m/s | in | mm | in | mm | |

| CAST IRON (Iron) | 0.179 | 4547 | 0.040 | 1.02 | 5.000 | 127.00 |

| SS 303 (SS303) | 0.223 | 5664 | 0.040 | 1.02 | 5.000 | 127.00 |

| STEEL 1018 (Steel) | 0.233 | 5918 | 0.040 | 1.02 | 5.000 | 127.00 |

| Al 2024 (Alum) | 0.251 | 6375 | 0.050 | 1.27 | 5.000 | 127.00 |

| PLEXIGLAS (Plexi) | 0.106 | 2692 | 0.040 | 1.02 | 2.000 | 50.80 |

| PVC (PVC) | 0.094 | 2388 | 0.035 | 0.89 | 2.000 | 50.80 |

| POLYSTYRENE (Poly) | 0.081 | 2057 | 0.035 | 0.89 | 2.000 | 50.80 |

Color Model (3) Only. A display in which the received pulse amplitude is represented along y axis and the travel distance of the ultrasonic pulse is represented along the x axis.

Color Model (3) Only. A display in which a cross sectional profile of the test material is represented.

The PosiTector UTG comes complete with ultrasonic gel, protective rubber holster with belt clip, wrist strap, 3 AAA alkaline batteries, instructions, protective lens shield, nylon carrying case with shoulder strap, Long Form Certificate of Calibration traceable to NIST, USB cable, PosiSoft Software, two (2) year warranty.

Do your instruments require any formal training for use? Do you offer ‘demo’ models?

No. Our instruments are designed for simple operation, feature easy-to-use menus, both full and quick instruction manuals, and helpful videos. In lieu of demonstration models, we provide unlimited technical support via telephone and/or email, and a limited 30-day money back guarantee.

Is the PosiTector UTG calibrated at the factory?

The PosiTector UTG arrives fully calibrated and ready to measure. A Long-Form Certificate of Calibration traceable to NIST is included, which documents actual readings taken by your instrument at our calibration laboratory on standards traceable to a national metrology institute. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements.

Verification of gage calibration and accuracy can be performed with the accessory Certified Step Block. If necessary, the PosiTector UTG operator can easily perform a calibration adjustment to align the gage’s thickness readings to match that of a known reference sample.

Can I measure the thickness of non-metallic materials like plastic and rubber with the PosiTector UTG?

Yes! The PosiTector UTG features several preprogrammed sound velocities for common materials. For best accuracy, make a simple adjustment to a known sample thickness of the material or quickly enter the material’s sound velocity into the gage. The PosiTector UTG C can be adjusted to a broad range of sound velocities spanning from 0.0492 to 0.393 mils/µs (1250 to 10000 m/s).

Can the PosiTector UTG measure cast/ductile iron or cast aluminum?

Our PosiTector UTG ultrasonic wall thickness instruments are designed to accurately measure the wall thickness of carbon steel, aluminum, stainless steel and plastic.

PosiTector UTG probes utilize a 5MHz transducer. Like other UT (ultrasonic wall thickness) gages utilizing a 5MHz transducer, the PosiTector UTG is challenged to provide reliable wall thickness measurements on cast metals including iron, aluminum and zinc. The internal structure of the cast metal typically interferes with the transmission of a 5MHz sound impulse causing the gage to yield inaccurate thickness readings.

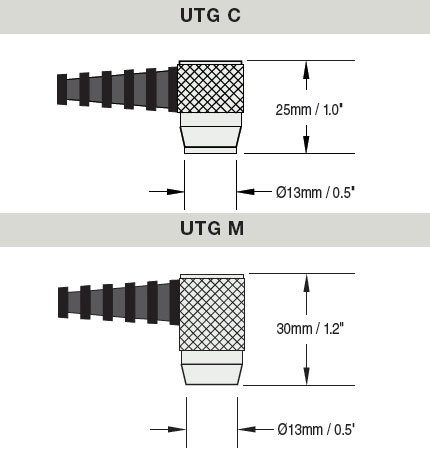

What is the difference between the PosiTector UTG C and PosiTector UTG M?

The PosiTector UTG C (Corrosion) single echo probe uses a dual-element transducer, a focused “V-path”, and V-path compensation to accurately measure the thickness of metals with particularly heavy corrosion or pitting. The UTG C single echo probe will not ignore the thickness of the exterior coating: for best measurement accuracy, it may be necessary to remove any coating present at the point of measurement.

The PosiTector UTG M (Multi-echo) probe uses a single element transducer to accurately measure the metal thickness of a new or lightly corroded structure while ignoring the thickness of protective coatings. The ultrasonic beam travels in a straight path to the material’s back wall at 90° relative to the surface. When three consecutive back wall echoes are detected, the probe makes a time-based calculation to eliminate the coating thickness from the gage reading.

If there is paint on the surface and it can’t be removed, can the PosiTector UTG C be used?

Yes, but coatings such as paint have a slower sound velocity than metal. This means that coating ‘appears’ much thicker to the instrument than it actually is, and can substantially affect the reading. Using Thru-Paint technology, the PosiTector UTG M multi-echo probe disregards the exterior coating thickness on a painted metal structure and reports only the metal thickness.

Can the UTG measure the thickness of materials with heavy corrosion on the back/inside?

The PosiTector UTG C (Corrosion) is a proven solution for measuring the thickness of metal structures with pitting and/or moderate-to-severe corrosion on the back wall.

How often should the PosiTector probe be recalibrated?

PosiTector probes include a Certificate of Calibration with no expiry or end date. They have no shelf life, therefore the length of time in the field is not a good indicator for recalibration intervals. Many organizations with quality programs and recertification programs require annual recalibrations, and this is a good starting point for most users. Manufacturers recommend that customers establish calibration intervals based upon their own experience and work environment. Based on our product knowledge, data and customer feedback, a one year calibration interval from the date the instrument was placed in service is a good starting point.

No. Our instruments are designed for simple operation, feature easy-to-use menus, both full and quick instruction manuals, and helpful videos. In lieu of demonstration models, we provide unlimited technical support via telephone and/or email, and a limited 30-day money back guarantee.

Is the PosiTector UTG calibrated at the factory?

The PosiTector UTG arrives fully calibrated and ready to measure. A Long-Form Certificate of Calibration traceable to NIST is included, which documents actual readings taken by your instrument at our calibration laboratory on standards traceable to a national metrology institute. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements.

Verification of gage calibration and accuracy can be performed with the accessory Certified Step Block. If necessary, the PosiTector UTG operator can easily perform a calibration adjustment to align the gage’s thickness readings to match that of a known reference sample.

Can I measure the thickness of non-metallic materials like plastic and rubber with the PosiTector UTG?

Yes! The PosiTector UTG features several preprogrammed sound velocities for common materials. For best accuracy, make a simple adjustment to a known sample thickness of the material or quickly enter the material’s sound velocity into the gage. The PosiTector UTG C can be adjusted to a broad range of sound velocities spanning from 0.0492 to 0.393 mils/µs (1250 to 10000 m/s).

Can the PosiTector UTG measure cast/ductile iron or cast aluminum?

Our PosiTector UTG ultrasonic wall thickness instruments are designed to accurately measure the wall thickness of carbon steel, aluminum, stainless steel and plastic.

PosiTector UTG probes utilize a 5MHz transducer. Like other UT (ultrasonic wall thickness) gages utilizing a 5MHz transducer, the PosiTector UTG is challenged to provide reliable wall thickness measurements on cast metals including iron, aluminum and zinc. The internal structure of the cast metal typically interferes with the transmission of a 5MHz sound impulse causing the gage to yield inaccurate thickness readings.

What is the difference between the PosiTector UTG C and PosiTector UTG M?

The PosiTector UTG C (Corrosion) single echo probe uses a dual-element transducer, a focused “V-path”, and V-path compensation to accurately measure the thickness of metals with particularly heavy corrosion or pitting. The UTG C single echo probe will not ignore the thickness of the exterior coating: for best measurement accuracy, it may be necessary to remove any coating present at the point of measurement.

The PosiTector UTG M (Multi-echo) probe uses a single element transducer to accurately measure the metal thickness of a new or lightly corroded structure while ignoring the thickness of protective coatings. The ultrasonic beam travels in a straight path to the material’s back wall at 90° relative to the surface. When three consecutive back wall echoes are detected, the probe makes a time-based calculation to eliminate the coating thickness from the gage reading.

If there is paint on the surface and it can’t be removed, can the PosiTector UTG C be used?

Yes, but coatings such as paint have a slower sound velocity than metal. This means that coating ‘appears’ much thicker to the instrument than it actually is, and can substantially affect the reading. Using Thru-Paint technology, the PosiTector UTG M multi-echo probe disregards the exterior coating thickness on a painted metal structure and reports only the metal thickness.

Can the UTG measure the thickness of materials with heavy corrosion on the back/inside?

The PosiTector UTG C (Corrosion) is a proven solution for measuring the thickness of metal structures with pitting and/or moderate-to-severe corrosion on the back wall.

How often should the PosiTector probe be recalibrated?

PosiTector probes include a Certificate of Calibration with no expiry or end date. They have no shelf life, therefore the length of time in the field is not a good indicator for recalibration intervals. Many organizations with quality programs and recertification programs require annual recalibrations, and this is a good starting point for most users. Manufacturers recommend that customers establish calibration intervals based upon their own experience and work environment. Based on our product knowledge, data and customer feedback, a one year calibration interval from the date the instrument was placed in service is a good starting point.

| Item | Description | Price | ||

|---|---|---|---|---|

UTGP1 | Ultrasonic Thickness Gauge, Standard Model with Precision Probe - PosiTector® | $1,460.00 | ||

| Accessories | ||||

PRBUTGC | PosiTector® UTG Corrosion Cabled Probe, Probe Only | $820.00 | ||

PRBUTGCA | PosiTector® UTG Corrosion Integral Probe, Probe Only | $895.00 | ||

PRBUTGCX | PosiTector® UTG Xtreme Corrosion Probe, Probe Only | $940.00 | ||

PRBUTGCLF | PosiTector® UTG Low Frequency Probe, Probe Only | $915.00 | ||

PRBUTGP | PosiTector® Precision Probe, Probe Only | $1,135.00 | ||

PRBUTGM | PosiTector® Multiple Echo Probe, Probe Only | $1,620.00 | ||

UTGPTRNSDCR | Replacement Precision Transducer for UTG P | $435.00 | ||

SoundSafe Coupling Fluid - 12 oz / 354 ml - NSN: 6635-01-553-0559 | $30.00 | |||

Bluetooth Printer for PosiTector Series Gauges | $340.00 | |||

PAPERBT | 10 Rolls of Paper for the Bluetooth Printer (PRINTERBT) | $20.00 | ||

USBAC | AC Power Adapter, 100-230V for PosiTector 6000 Display | $45.00 | ||

LENSSHIELD | Protective Lens Shields, Pack of 5 for PosiTector® 6000 Display | $10.00 | ||

STDB1 | 5 Step Certified Steel Block with inch units, 100, 200, 300, 400, 500 mil steps | $435.00 | ||

STDB1M | 5 Step Certified Steel Block with metric units, 2.5, 5, 7.5, 10, 12.5 mm steps | $485.00 | ||

GEL-P | Case of 12 bottles of Couplant, 4oz each for PT-200 / PT-UTG | $195.00 | ||

GEL-T | Case of 2 bottles of Couplant, 4oz each | $47.00 | ||

In stock

1 Week Lead Time (Estimated)

2-3 Week Lead Time (Estimated)

Lead Time Varies, Please contact us for availability.

Unavailable