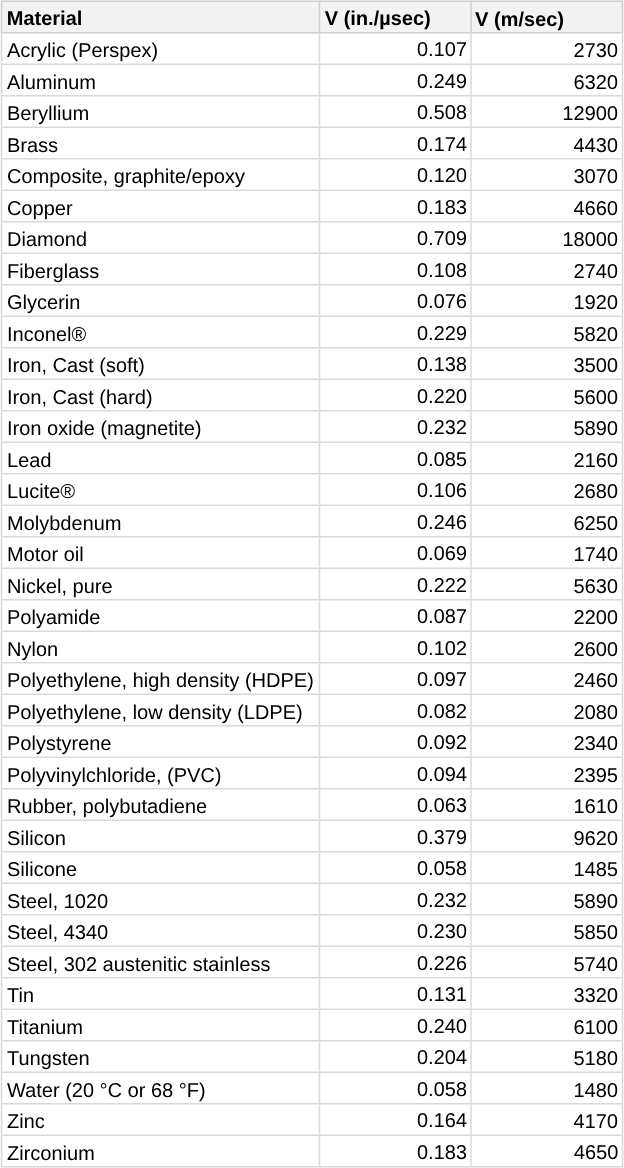

The table below lists the sound velocities of common materials that can be measured with ultrasonic thickness gauges. Note that this is only a general guide. The actual velocity in these materials may vary significantly due to a variety of causes such as specific composition or microstructure, grain or fiber orientation, porosity, and temperature. This is especially true in the case of cast metals, fiberglass, plastics, and composites. For best accuracy in thickness gauging, the sound velocity in a given test material should always be measured by performing a velocity calibration on a sample of known thickness.

| Material | V (in./µsec) | V (m/sec) |

|---|---|---|

| Acrylic (Perspex) | 0.1070 | 2730 |

| Aluminum | 0.2490 | 6320 |

| Beryllium | 0.5080 | 12900 |

| Brass | 0.1740 | 4430 |

| Composite, graphite/epoxy | 0.1200 | 3070 |

| Copper | 0.1830 | 4660 |

| Diamond | 0.7090 | 18000 |

| Fiberglass | 0.1080 | 2740 |

| Glycerin | 0.0760 | 1920 |

| Inconel® | 0.2290 | 5820 |

| Iron, Cast (soft) | 0.1380 | 3500 |

| Iron, Cast (hard) | 0.2200 | 5600 |

| Iron oxide (magnetite) | 0.2320 | 5890 |

| Lead | 0.0850 | 2160 |

| Lucite® | 0.1060 | 2680 |

| Molybdenum | 0.2460 | 6250 |

| Motor oil | 0.0690 | 1740 |

| Nickel, pure | 0.2220 | 5630 |

| Polyamide | 0.0870 | 2200 |

| Nylon | 0.1020 | 2600 |

| Polyethylene, high density (HDPE) | 0.0970 | 2460 |

| Polyethylene, low density (LDPE) | 0.0820 | 2080 |

| Polystyrene | 0.0920 | 2340 |

| Polyvinylchloride, (PVC) | 0.0940 | 2395 |

| Rubber, polybutadiene | 0.0630 | 1610 |

| Silicon | 0.3790 | 9620 |

| Silicone | 0.0580 | 1485 |

| Steel, 1020 | 0.2320 | 5890 |

| Steel, 4340 | 0.2300 | 5850 |

| Steel, 302 austenitic stainless | 0.2260 | 5740 |

| Tin | 0.1310 | 3320 |

| Titanium | 0.2400 | 6100 |

| Tungsten | 0.2040 | 5180 |

| Water (20 °C or 68 °F) | 0.0580 | 1480 |

| Zinc | 0.1640 | 4170 |

| Zirconium | 0.1830 | 4650 |