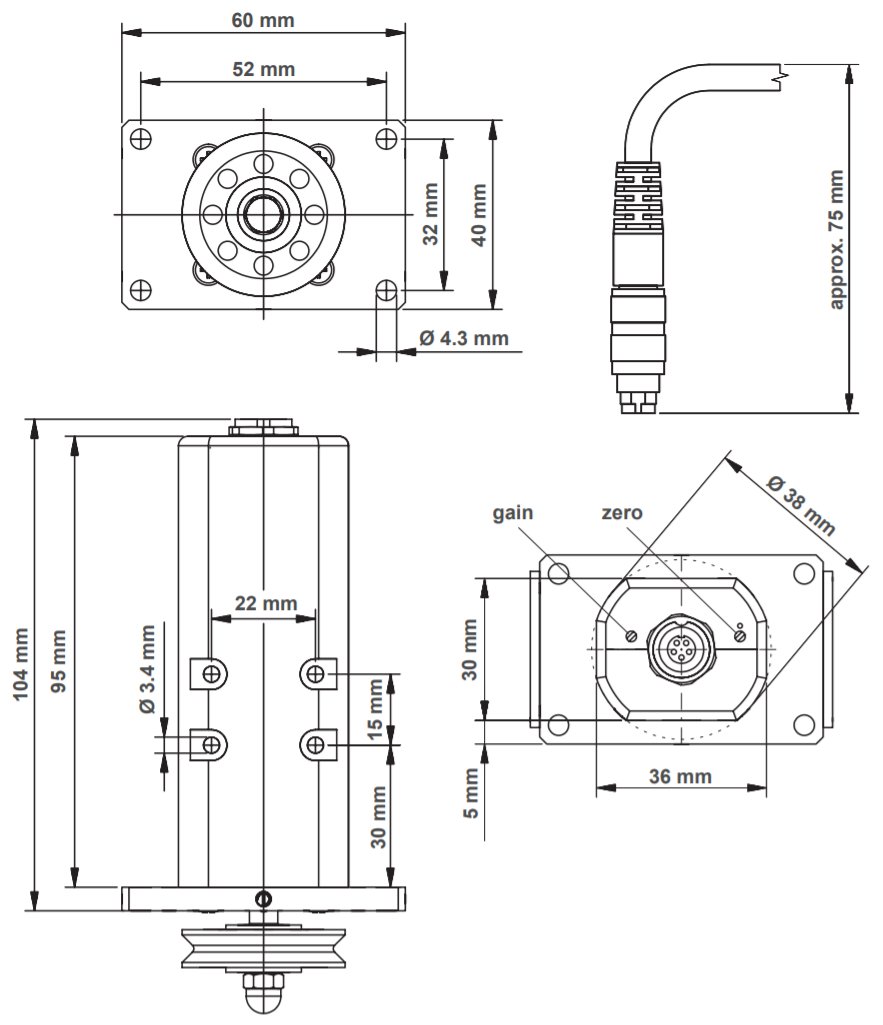

Fined-mounted tension sensor, single rollers system, for mounting at an existing location to create a fixed wrap angle of the material over the sensor rollers.

29.5mm diameter hardened steel v-grooved roller is standard. Optional rollers include a U-Grooved Roller with 5mm radius, 70mm diameter lightweight roller for optic fibers and similar fragile filaments as well as ribbon rollers for flat materials such as tapes/bands, tows, ribbon cable, rectangular wires and similar flat materials.

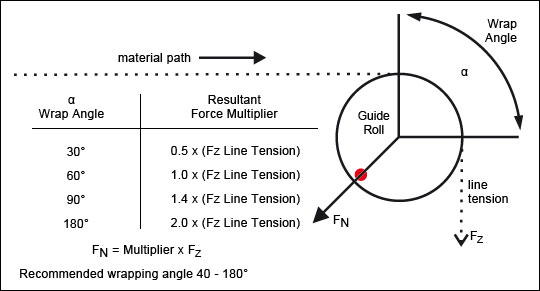

5 ranges are offered from 0-10N (1Kg) up to 0-200N (20 Kg), rated in resultant force (therefore wrap angle must be taken into account and resultant force calculated)

29.5mm diameter hardened steel v-grooved roller is standard. Optional rollers include a U-Grooved Roller with 5mm radius, 70mm diameter lightweight roller for optic fibers and similar fragile filaments as well as ribbon rollers for flat materials such as tapes/bands, tows, ribbon cable, rectangular wires and similar flat materials.

5 ranges are offered from 0-10N (1Kg) up to 0-200N (20 Kg), rated in resultant force (therefore wrap angle must be taken into account and resultant force calculated)

- Includes integrated amplifier with "zero" and "gain" adjustment pots

- Standard output is 0-1V DC

- Optional outputs include 0-10V DC, 4-20mA, USB, RS-232 and RS-422

- Optional Wi-Fi cable free data transfer available requires use of battery pack for sensor

- Sensor can be mounted using holed in sensor body or front plate of sensor

- Features full bridge strain gauge sensing for highest accuracy

- Requires 15-24V DC regulated power for sensor excitation

- Optional Digital Tension Indicators are offered

| Model | Resultant Force Capacity (g/Kg) | Resultant Force Capacity (Newtons) |

|---|---|---|

| FSR-10N | 1000g / 1 Kg | 0 – 10 N |

| FSR-20N | 2000g / 2 Kg | 0 – 20 N |

| FSR-50N | 5Kg | 0 – 50 N |

| FSR-100N | 10Kg | 0 – 100 N |

| FSR-200N | 20 Kg | 0 – 200 N |

| FSR-500N | 50 Kg | 0 - 500N |

The tension range can be calculated for every wrapping angle with this formula:

FN = Nominal load (Multiplier * FZ)

FZ = Line Tension

α = Wrapping angle at the guide roll

FN = 2 * FZ * sin( α/2 )

When selecting the nominal measurement force it is necessary to take into account the weight of the guide roll and raise the nominal load respectively, particularly when working with small nominal forces.

| Roller Code | Diameter / Width | Max Line Speed (m/min) | Roller Material |

|---|---|---|---|

| Standard | 29.5 mm (V-Groove) | 4000 | Hardened Steel |

| R1 | 29.5 mm (U-Groove, R5) | 4000 | Hard Chrome-Plated Steel |

| F | 70 mm (V-Grooved) | 4000 | Hard-Coated aluminium |

| FB | 70 mm (V-Grooved) | 4000 | Tempered Steel |

| B6 | 29.5 mm (6mm width) | 2000 | Hardened Steel, Ribbon Roller |

| B10 | 29.5 mm (10mm width) | 2000 | Hardened Steel, Ribbon Roller |

| Calibration | According to the factory calibration procedure |

| Accuracy | ±1.5 % full scale and ±1 digit % full scale or better other calibration material ±3 % full scale or better |

| Overload Protection | 100% of tension range |

| Measuring principle | Strain gauge bridge (Load Cell) |

| Measuring roller deflection | 0.5 mm, max |

| Temperature drift | Less than ±0.05 % full scale/ºC |

| Output signal | Standard: 0 – 1 V DC Option DC: 0 - 10V DC Option MA: 4-20mA Option USB: USB Output Option 232: RS-232 (200Hz) Option 422: RS-422 (200Hz) Option WL: Wi-Fi Output |

| Damping | Standard: 30 Hz (other values on request) |

| Temperature Range | 10 – 45 ºC |

| Air Humidity | 85 % RH, max. |

| Power supply | +15…24 V DC, max. 50 mA regulated |

| Housing Material | Aluminium |

| Weight, net (gross) | Approx. 250 g (Approx. 350 g) |