4 Tension Ranges from 0-100 g up to 0-1000 g

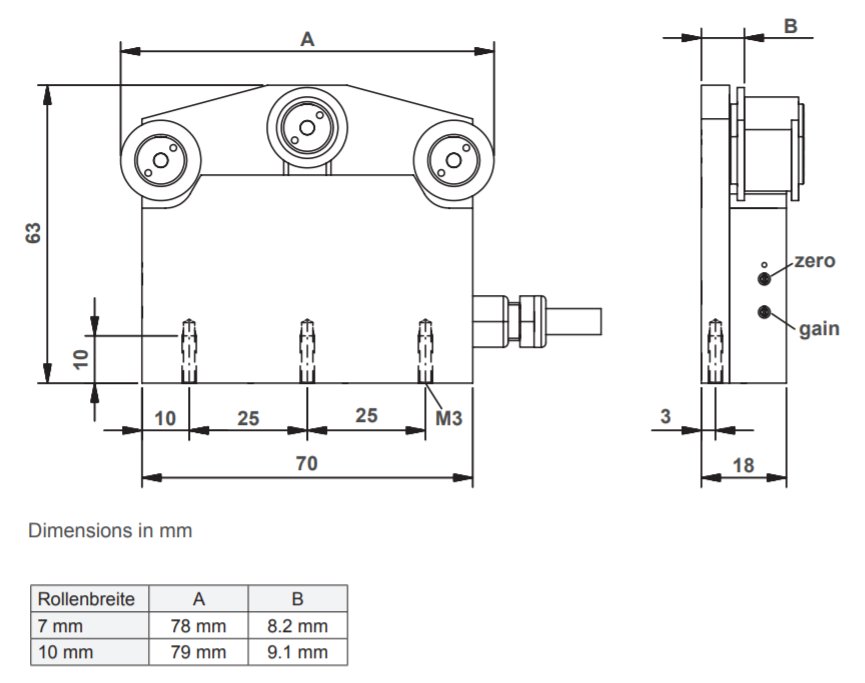

2 Roller Widths; 7 or 10 mm

Can be supplied with V-Grooved or U-Grooved Rollers, TSC-Series

Built-in signal conditioning with ZERO and SPAN pots provide a high-level, analog output to minimize the chance for signal interference.

Can be used for process diagnostics, for continuously monitoring and recording of online tensions. The TSCB Series Tension Sensor can also be used as part of a closed-loop control system with 3rd-Party controller.

Can be used for process diagnostics, for continuously monitoring and recording of online tensions. The TSCB Series Tension Sensor can also be used as part of a closed-loop control system with 3rd-Party controller.

Mounting possibilities: Sensor can be mounted on a flat plate using the supplied thru holes on the underside of the housing body or fixed on the optional rail allowing for quick, easy installation and allows for multiple sensors mounted adjacent to one another with minimal spacing.

- Strain Gauge-based sensor provides accuracy of 2% Full Scale or better. Sensor can be mounted in any orientation depending upon the material path.

- Built-in Signal Conditioner provides 0-1 V DC Analog Output (0-10V or mv/V, optional) with Integrated Zero & Gain Pots on rear-side of sensor allowing for convenient calibration by the end-user for highest accuracy

- Supplied with easy-running ball-bearing mounted, flat cylindrical rollers with flanges.

- 7 mm wide roller is fabricated from nickel-plated steel, 10 mm roller is hardcoat anodized aluminum

- Rollers can be supplied with a special carbon-optimized coating ("orange peel"), Option Code CF

- Can be used together with SC-PM, PD765 Digital Tension Indicator or with user-supplied electronics (requires 15-24 V DC regulated power).

- 3-Roller design insures that the center sensor rollers has the same wrap angle at all times which allows the sensor to be mounted in any position on the line

- Sensor can be mounted on a flat plate using the supplied thru holes on the underside of the housing body or fixed on the optional rail allowing for quick, easy installation

- Slim Sensor Housing allows for multiple sensors mounted adjacent to one another with minimal spacing

- Includes 3 meter (9 ft) length integrated cable with open ends for connection to Tension Indicator or user-supplied electronics

| Model | Range | Measuring Head Width* | Roller Width** |

|---|---|---|---|

| TSCBB-100-7 | 0 - 100 g | 70 mm | 7 mm |

| TSCBB-200-7 | 0 - 200 g | 70 mm | 7 mm |

| TSCBB-500-7 | 0 - 500 g | 70 mm | 7 mm |

| TSCBB-1000-7 | 0-1000 g | 70 mm | 7 mm |

| TSCBB-100-10 | 0 - 100 g | 70 mm | 10 mm |

| TSCBB-200-10 | 0 - 200 g | 70 mm | 10 mm |

| TSCBB-500-10 | 0 - 500 g | 70 mm | 10 mm |

| TSCBB-1000-10 | 0-1000 g | 70 mm | 10 mm |

* Outside dimensions of the housing

** Outside dimensions of the roller

| Standard | 0 - 1 V DC (analog) |

| Option | Code DC: 0 - 10 V DC |

| Option | Code A10: Direct strain gauge output signal 2mV/V without amplifier |

| Accuracy | ±2% full scale and ±1 digit |

| Overload protection | 100% of tension range |

| Measuring principle | Strain gauge bridge |

| Measuring roller deflection | max. 0.5 mm |

| Signal processing | analog |

| Output signal | Standard: 0-1 V DC (analog) Option: 0-10 V DC (Option "DC") or 2mV/V Direct Strain Gauge Output (Option "A10") |

| Option "A10" Output | 0.6 +/- 0.12 mV / V, 5V DC (max) power required (3-5V DC) |

| Cable | Shielded cable (2 m) with open ends |

| Damping (fg) | Standard (analog): 30 Hz |

| Temperature drift | better ± 0.05 % FS/ °C |

| Temperature range | 10 - 45 °C |

| Air humidity | 85 % RH, max. |

| Power supply | + 15 ... 24 V DC, 21 mA (regulated); |

| Housing | Aluminium, with threaded mounting holes on underside (M3 Thread) |

| Housing dimensions | 70 x 55 x 17 mm (L x W x H) |

| Weight, net | Approx. 100 g |

| Connection to PD765 | SIGNAL: Yellow (Sig+) to V+, Green (Sig-) to COM DC-POWER:White (Exc+) to P2+, Brown (Gnd) to P2- |