Hardness testing on convex and concave surfaces: Unlike the conventional hardness testers which are limited to only flat-surfaced samples, measuring with the Bareiss digitest II allows hardness testing on all surfaces possible by using the automatic surface detection technology. In addition to that, we can customize our indenter length so that it can reach any point on the sample which is required for measuring.

Sample holders and positioning devices: Bareiss offers a wide range of standard sample holders, but we also specialize in customizing holders for your particular products. Please contact the sales team for your individual solution.

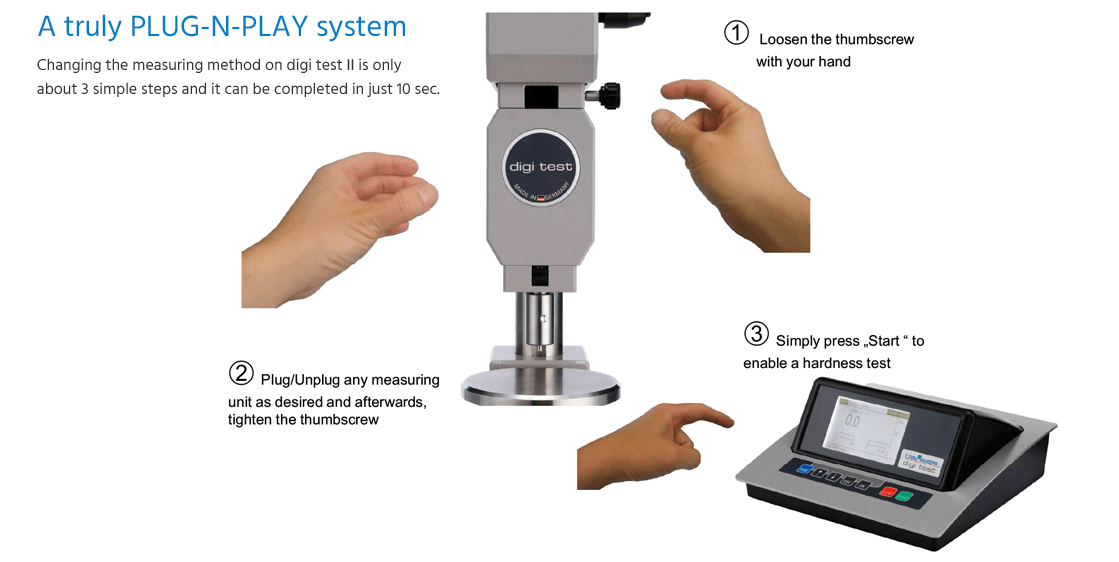

Measuring Devices: The easy plug-and-play solution requires no complicated setup. The measuring unit can be securely installed simply by hand fastening a knurl nut and once done, the electronic unit automatically detects the type of the installed measuring method in accordance to that standard.

| Test Method | Range of Application | Standard | Minimum material thickness [mm] | Mode |

|---|---|---|---|---|

| Shore A | soft rubber, elastomers, natural rubber products, neoprene, casting resin, polyester, soft PVC, leather, pressure rollers, etc | DIN EN ISO 868 | 4 | Standard Std. Graph |

| DIN ISO 7619, ASTM D 2240, NFT 51-174, BS903 Part. A 26 | 6 | |||

| Shore B | middle hard materials from rubber, typewriter roles, flat materials | ASTM D 2240 | 6 | Standard Std. Graph |

| Shore 0 | soft elastic materials, pressure rolls, middle firm, textile fabrics, nylon, orlon, perlon, rayon | ASTM D 2240 | 6 | Standard Std. Graph |

| Shore A0 Shore E | Soft foam, leather covers | DIN ISO 7619

ASTM D 2240 |

6 | Standard Std. Graph |

| M Shore A M Shore A/B/0 | Shore A | Bareiss Standard | 1.5 | Standard Std. Graph |

| Shore D | hard rubber, hard plastics, acrylic glass, polystyrene, rigid thermoplastics, Resopal, pressure rollers, Vinyl plates, cellulose- Acetate, etc. | DIN EN ISO 868 | 4 | Standard Std. Graph |

| DIN ISO 7619,

ASTM D 2240, NFT 51-174, BS903 Part. A 26 |

6 | |||

| M Shore D/C/D0 | Shore D 0,5 Molded parts | Bareiss Standard | 1 | Standard Std. Graph |

| Shore C | plastics and middle hard rubber materials | ASTM D 2240 | 6 | Standard Std. Graph |

| Shore D0 | plastics and middle hard rubber materials | ASTM D 2240 | 6 | Standard Std. Graph |

| Shore 00 | sponge- and foam rubber, cellular rubber, silicone | ASTM D 2240 | 6 | Standard Std. Graph |

| Shore 000 | sponge- and foam rubber, cellular rubber, silicone | ASTM D 2240 | 6 | Standard Std. Graph |

| Shore 000 S | sponge- and foam rubber, cellular rubber, silicone | ASTM D 2240 | 6 | Standard Std. Graph |

| Shore AM/M | Shore A | DIN ISO 7619

ASTM D 2240 |

1.5 | Standard Std. Graph |

| IRHD M | Thin-walled O-rings, molded parts, norm plates | DIN ISO 48

ASTM D 1415 |

1 | Standard Std. Graph Hysteresis |

| IRHD H | Shore D | DIN ISO 48

ASTM D 1415 |

6 | Standard Std. Graph Hysteresis |

| IRHD N | Soft rubber, high elastic materials, plastic ductile materials | DIN ISO 48

ASTM |

6 | Standard Std. Graph Hysteresis |

| IRHD L | Moss- and cell rubber, foam rubber, silicone | DIN ISO 48,

ASTM D 1415 |

10 | Standard Std. Graph Hysteresis |

| VLRH | Moss- and cell rubber, foam rubber, silicone | DIN ISO 27588

DIN ISO 48-3 |

2 | Standard Std. Graph Hysteresis |

| Test Method | Spring Force (mN) | Indenter | Measuring distance (mm) | Total weight | Additional weight |

| Shore A | 8050 | 350 | 2.5 | 1kg | - |

| Shore AM/M | 764 | 300 | 1.25 | 250g | - |

| Shore E | 8050 | Ø 5mm | 2.5 | 1kg | - |

| Shore A0 | 8050 | Ø 5mm | 2.5 | 1kg | - |

| L/Lc | 8050 | Ø 5mm | 2.5 | 1kg | - |

| Shore D | 44450 | 300 | 2.5 | 5kg | 0.250 g |

| 3.75 kgs | |||||

| Shore B | 8050 | 300 | 2.5 | 1kg | - |

| Shore C | 44450 | 350 | 2.5 | 5kg | 0.250 g |

| 3.75 kgs | |||||

| Shore D0 | 44450 | 3/320 | 2.5 | 5kg | 0.250 g |

| 3.75 kgs | |||||

| Shore 0 | 8050 | 3/320 | 2.5 | 1kg | - |

| Shore 00 | 1111 | 3/320 | 2.5 | 400g | - |

| Shore 000 | 1111 | r= 6.35mm | 2.5 | 400g | - |

| Shore 000 S | 1932 | r= 10.7 | 5.0 | 400g | - |

| M Shore A | 108 | 300 | 1 | 23.5g | - |

| M Shore D | 9213 | 300 | 0.5 | 500g | - |

| IRHD M | 153.3 | Ø 0.4mm | 0.3 | 235mN | - |

| IRHD N | 5.7N | Ø 2.5mm | 1.8 | 8.3N | - |

| IRHD H | 5.7N | Ø 1.0mm | 0.44 | 8.3N | - |

| IRHD L | 5.7N | Ø5.0mm | 2.1 | 8.3N | - |

| VLRH | 100 | Ø 2.5mm | 1 | 235mN | - |

| Power Supply | 100-240 VAC, 50/60 Hz | |

| Power consumption | Max. 20 VA | |

| Kind of protection | IP 20 | |

| Display | LCD- graphical display (240 *128 pixels) with LED illumination | |

| Resolution | 0.1 | |

| Measuring time | 1-99 sec | |

| Data output | USB RS 232 – 9600 Baud, 1 start bit, 8 Data Bits, 1 Stop bit | |

| Connections | Pick up the bracket with the measuring device, Barofix II | |

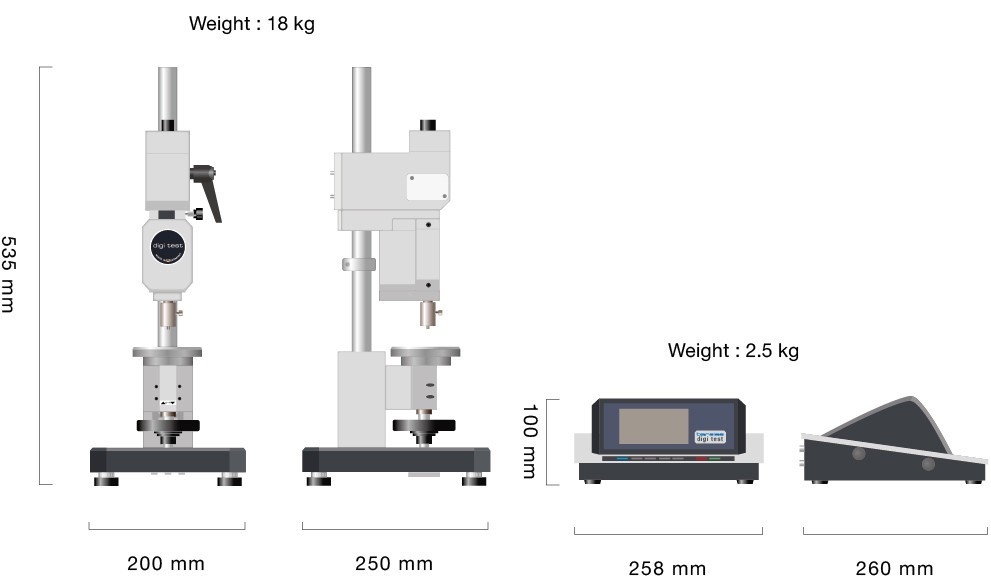

| Dimensions ( L*W*H), Weights | Test stand: 200 * 250 * 570 mm | 9.0 kgs |

| Pick up bracket: 165 * 135 * 60 mm | 3.0 kgs | |

| Electronic unit: 260 * 260 * 110 mm | 2.0 kgs | |

| Measuring devices: 150 * 70 * 60 mm | ||

| IRHD M, M Shore A, VLRH | 0.8 kgs | |

| IRHD N, L, H | 1.8 kgs | |

| Shore A/B/0 | 1.5 kgs | |

| Shore D/C/D0 | 0.4 kgs | |

| M Shore D/C/D0, M Shore A/B/0 | 0.9 kgs | |

| Shore for Asker C, CS | 0.9 kgs | |

Measuring devices Shore, A, B,0, D, C, D0, 00, 000, 000S, Asker C, CS:: 1) The electronic unit is switched on and using devices for shore D, C, D0, Asker CS the display shows: Apply additional weights and the loads are applied accordingly. 2) The sample is placed onto the supporting table so that there is proper contact between the surface of the supporting table and the sample. 3) Results are more reliable and precise when the highest point of the sample is below the indenter. 4) The supporting table is moved by hand wheel so that the distance between the indenter and the test specimen is 3mm 5) Press the ‘START’ key and the measuring device is automatically lowered onto the test specimen. 6) Once the measuring time is completed the measuring device moves back to its starting position and the measured value is shown on the display and the data can be transmitted simultaneously. Measuring device Shore, A/B/0:: 1) The loading weight on this measuring device should be in a free-moving position. If it’s fixed in the upper position, push up and rotate against the arrow direction. 2) Care must be taken to check that the indenter is not visible during testing as the loading weight must be movable freely. Measuring device M Shore, A/B/0, M Shore D: 1) The knurled screw is loosened until the loading weight can be moved freely. 2) Care must be taken to check that the indenter is not visible during testing as the loading weight must be movable freely. Measuring device M Shore, A/B/0, M Shore D:: 1) The knurled screw of the pressure plate must be loosened so that the pressure plate can be moved freely. 2) Care must be taken to check that the indenter is not visible during testing as the pressure plate must be movable freely.

- User-Friendly: This automatic shore hardness tester is equipped with an electronic unit that can show user information, time, and method of measurement, and is equipped with various other configurations along with automatic measurement of time and range detection.

- Range of Measurement: This Automatic hardness testing machine can measure the hardness of O rings, seals, rubbers, and plastics by making use of special measuring devices for which the fixtures can also be customized according to the sample that is to be tested.

- Mechanism: The measuring devices have an easy plug-and-play solution with no complex mechanism. The measuring devices can easily be fastened by hand using the knurled nut and the electronic unit can easily detect the device once it is set up.

- Complexity: Concave and convex samples can easily be tested for their shore hardness using the special measuring devices developed by Bareiss.

- Special Features: The hysteresis function is available in Micro, IRHD and VLRH methods, providing a better understanding of the results for further analysis.

- Integratable in an automatic production process.

| DIN ISO 7619 | |

| DIN ISO 48 | |

| DIN EN ISO 868 | |

| NF EN ISO 868 | |

| ASTM D 2240 | |

| BS 903 Part. A 26 | |

| NF T 46-003 | |

| ASTM D1415 | |

| DIN ISO 27588/ 48-3 |

The system consists of 4 components, a loading unit, measuring unit, stand, and an electronic display.

The system consists of 4 components, a loading unit, measuring unit, stand, and an electronic display.

The loading unit sits on top of the system and is connected to the display. It applies the required load as specified by the test method.

Measuring units are plug-and-play and available for all the options of Shore and IRHD standards.

The test stand is 22.5" / 570mm tall and the solid construction provides a rigid backbone for the entire system. It is key for generating precise and repeatable measurements.

Thank You

Thank you for your quote request, we will contact you within 1-2 business days.