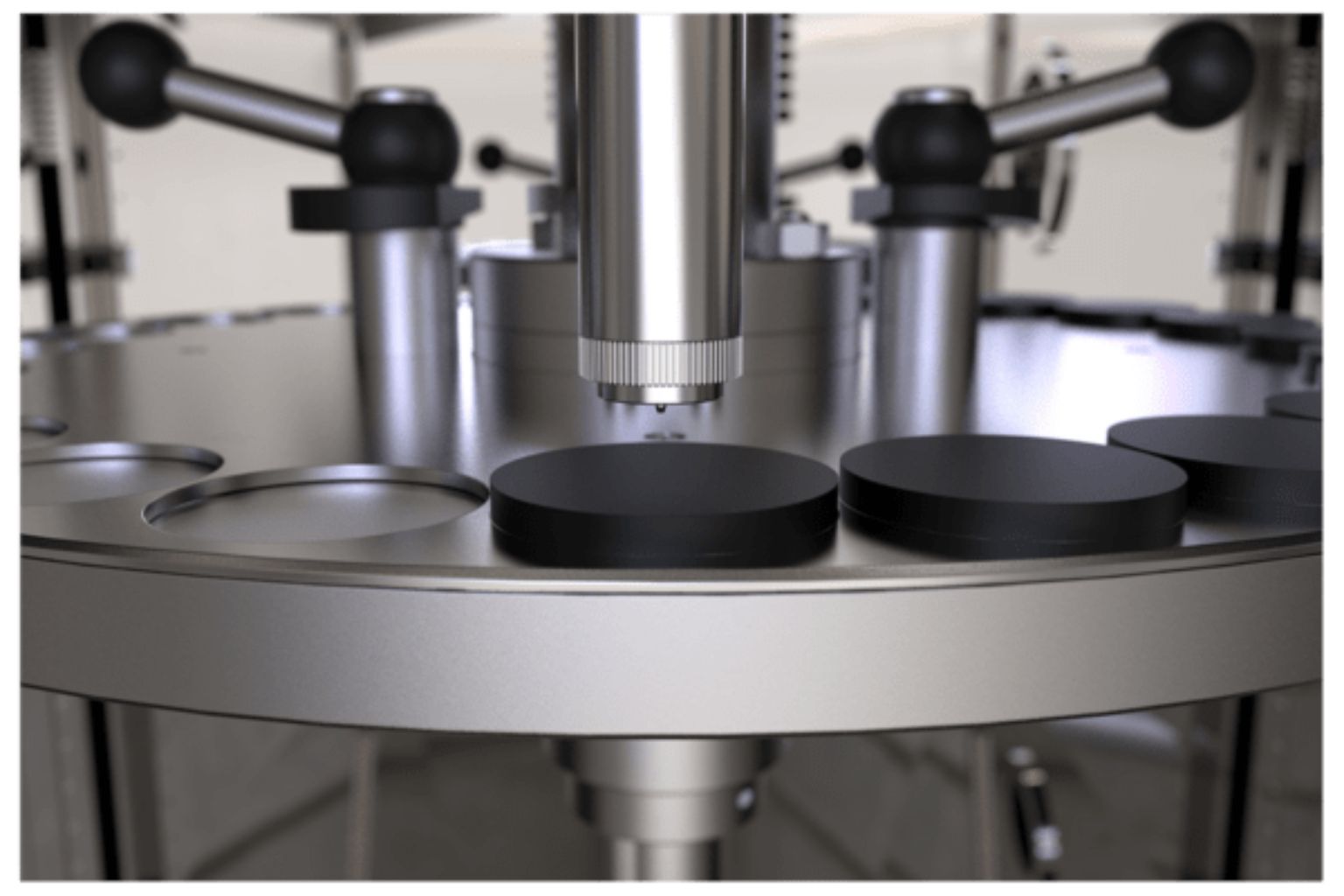

digiChamber is an “Environmental Chamber Rubber-Hardness tester” designed and developed by Bareiss that uses the most advanced technology to analyze the hardness of rubber under extreme conditions using Shore hardness A or IRHD N testing methods. This automatic testing device plays a major role in the automotive and tire industries as most of the rubber parts are required to sustain very extreme temperature variations. This multifeatured temperature-controlled hardness tester can carry out multiple tests simultaneously, making it one of the most popular testing devices in the market, also because of its reproducibility and accuracy of results it provides. digiChamber uses digiCenter software which makes it more convenient to operate and function efficiently. It also provides multiple features like, user management, user-defined testing sequence, and criteria, customized test reports, and exporting the data according to user formats.

- Large display: This advanced automatic hardness testing device has a 7” display which is controlled by a touch screen panel, supporting multiple languages.

- User Friendly: This advanced testing device has a user-friendly interface that makes it more popular in the market, by minimizing the training time. This added value is important to many companies.

- It consists of an air-cooled refrigeration unit with continuously variable power adjustment by SIMPAC and a chloride-free refrigeration cycle.

- A large test volume of 200 liters with polished stainless-steel walls for a test load of up to 125 kgs.

- Easy to use an electronic display with digital I/O for controlling the hardness system.

- Special Feature: The automatic tray can carry up to 25 pcs of samples and the user can select a test sequence by choosing multiple measurements on a sample along with the desired temperature.

- Temperature: Under extreme cold temperatures, rubber becomes hardened, and this can be simulated in an environment as cold as -40 0C with digiChamber. Under extreme high heat conditions of up to +180 0C temperature, rubber can be analyzed with this automatic digiChamber.

- Software (digiCenter): For all data logging and analysis, digiCenter has a user-friendly GUI (Graphic User Interface) for users to easily navigate through the software and quickly become familiar with it.

| Shore A hardness system | |

|---|---|

| Standards | DIN ISO 48-4, ASTM D 2240 |

| Spring force | 8050 mN |

| Force on the presser foot | 1kg |

| Presser foot size | Ø 18mm |

| Indenter | 35” |

| Penetration | 2.5 mm |

| IRHD N hardness system (optional) | |

| Standards | DIN ISO 48-2, ASTM D 1415 |

| Initial load | 0.3 N |

| Primary load | 5.7 N |

| Force on the presser foot | 8.3 N |

| Presser foot size | Ø 20 mm |

| Indenter | Ø 2.5 mm |

| Penetration | 1.8 mm |

| Temperature Chamber | |

| Temperature range | -70° C to 180° C |

| Recommended max temperature | 150° C |

| Temperature rate of change | ±0.2 K to ±0.5 K |

| Temperature homogeneity | ±0.5 K to ±1.5 K |

| Test volume | Approximate 200 liters |

| Heat compensation | 800 W |

| Noise level | 56 dB(A) |

| Refrigerant | Chloride-free R449A |

| Electrical and interfaces | |

| Voltage | 100-240 VAC, 50/60 Hz; 12 A |

| Power | Approx. 1.8 kW |

| Protection Class | IP 54 |

| USB | 3.0 (1 port) |

| Ethernet | 100/10 megabit |

| Compressed air | |

| Pressure | 4- 12 bar |

| Consumption | max. 6 m3/h |

| Coupling type | DN 7.2 |

| Sample Geometry: O-rings; Sheet material Shaped; Parts and thin specimens | |

| Type | Plate shape samples |

| Standard | Ø 38 mm / 50 mm others on request |

- Hardness scales interchangeable between Shore A and IRHD N

- 7” touch screen

- electronic console

- a large testing chamber having a capacity up to 200 liters

- air-cooled refrigeration unit

Thank You

Thank you for your quote request, we will contact you within 1-2 business days.

There was an error submiting the form. Please try again.