12 tension ranges from 0.2 - 200 grams up to 0.6 - 60 Kg, Wire Diameters up to 3mm

The Checkline DTS Digital Tension Meter accurately measures the running line tensions of yarns, fibers, wires, cables, optic fibers and similar materials. An auto-rotating display and auto-zeroing allow for simple measurement of material running in any orientation.

Special version models available for tapes and films, narrow access and larger diameter applications.

- NIST-Traceable Calibration Certification OPTIONAL

- V-Grooved Rollers Fabricated from Hardcoat Anodized Aluminum for material Speeds up to 2000 m/min

- Optional Rollers/Bearings for 3500 m/min or 5000 m/min

- Large, backlight LCD-display with 3 user-selected display modes: Large-numeric, Numeric with Bar Graph, Numeric with Trend Graph (tension vs time)

- Display automatically rotates in 90° steps (or can be locked in any desired position)

- Selectable units of measurement: Grams, cN, Kg, daN, Lbs and Newtons (N)

- Built-in Diameter Compensator System is used to adjust calibration curve for highest accuracy. Diameter is set with wheel and shown on display

- Automatic "Zero-Setting" in all measuring positions using built-in gravity sensor

- Storage for 4 Custom Material Calibrations

- Storage of Min, Max and Last reading as well as Hi-Peak, Low-Peak, average and standard deviation (per measuring interval)

- High speed internal data sampling (1000 samples/sec) for capture of accurate Min & Max Peaks

- Setup parameters can be password protected so they are not accidentally changed by the user

- User-set Min and Max alarms with indication on LCD if reading is out of limits

- User-adjustable DAMPING is used to minimize tension fluctuations

- Re-chargeable Lithium Polymer battery lasts 40 hours (continuous use, approx)

- Rugged aluminium housing with rubberized handle provides a secure and comfortable grip

- Warranty: 1-Year

- Made in Germany

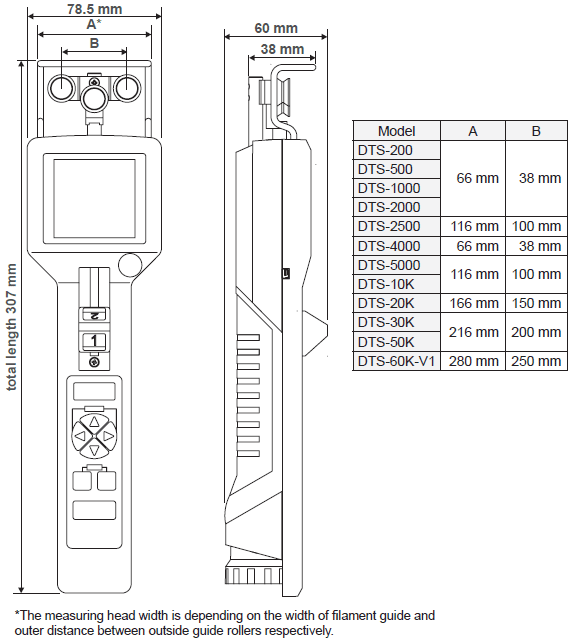

| Model | Tension Range | Resolution | Measuring Head Width* |

|---|---|---|---|

| DTS-200 | 0.2 - 200.0 grams or cN | 0.1 | 66 mm |

| DTS-500 | 0.5 - 500.0 grams or cN | 0.1 | 66 mm |

| DTS-1000 | 10 - 1000 grams or cN | 1 | 66 mm |

| DTS-2000 | 20 - 2000 grams or cN | 1 | 66 mm |

| DTS-2500 | 25 - 2500 grams or cN | 1 | 116 mm |

| DTS-4000 | 40 - 4000 grams or cN | 1 | 66 mm |

| DTS-5000 | 50 - 5000 grams or cN | 1 | 116 mm |

| DTS-10K | 0.1 - 10.00 Kg or daN | 0.01 | 116 mm |

| DTS-20K** | 0.2 - 20.00 Kg or daN | 0.01 | 166 mm |

| DTS-30K** | 0.3 - 30.00 Kg or daN | 0.01 | 216 mm |

| DTS-50K** | 0.5 - 50.00 Kg or daN | 0.01 | 216 mm |

| DTS-60K-V1** | 0.6 - 60.00 Kg or daN | 0.01 | 280 mm |

* Depending on model, either width of filament guide or outer distance between outside guide rollers

**Lever no longer required for high capacity models

**Lever no longer required for high capacity models

| Model | Applications textile industry | Applications wire industry | Calibration Material PA*** | Material thickness compensator |

|---|---|---|---|---|

| DTS-200 | max. 200 TEX | max. 0.15 mm Ø | 0.12 mm Ø | |

| DTS-500 | max. 500 TEX | 0.05 - 0.25 mm Ø | 0.12 + 0.20 mm Ø | |

| DTS-1000 | max. 1000 TEX | 0.10 - 0.40 mm Ø | 0.20 + 0.40 mm Ø | |

| DTS-2000 | max. 2000 TEX | 0.30 - 0.60 mm Ø | 0.40 + 0.70 mm Ø | |

| DTS-2500 | max. 2500 TEX | 0.30 - 0.70 mm Ø | 0.40 + 0.70 mm Ø | |

| DTS-4000 | max. 4000 TEX | 0.35 - 0.90 mm Ø | 0.50 + 0.90 mm Ø | |

| DTS-5000 | max. 5000 TEX | 0.40 - 1.00 mm Ø | 0.60 + 1.20 mm Ø | |

| DTS-10K | max. 10000 TEX | 0.70 - 1.20 mm Ø | 0.80 + 1.40 mm Ø | |

| DTS-20K | max. 20000 TEX | 1.00 - 2.00 mm Ø | 1.20 + 1.80 mm Ø | |

| DTS-30K | max. 30000 TEX | 1.20 - 2.50 mm Ø | 1.40 + 2.20 mm Ø | |

| DTS-50K | max. 50000 TEX | 1.40 - 3.00 mm Ø | steel rope 1.5mm Ø (7x7x0.2) | |

| DTS-60K-V1 | max. 60000 TEX | 1.80 - 3.50 mm Ø | steel rope 2.0mm Ø (7x7x0.3) |

*** Suitable for 95 % of applications

| V1 Rollers, Supplied on DTS-60K-V1 | Image | Dimensions |

|---|---|---|

| Center Roller Max Speed: 1000 m/min Material: Hard-Coated Aluminum Part Number: R12900 |

|

|

| Outer Rollers Max Speed: 1000 m/min Material: Hard-Coated Aluminum Part Number: R12902 |

|

|

| Code | Line Speed Vmax ...m/min |

Roller Material |

|---|---|---|

| Standard | 2000 | Hardcoated aluminium |

| Code K | 3500 | Hardcoated aluminium |

| Code H | 5000 | Plasma-coated aluminium |

| Code T | 1000 | Plastick (POM) black |

| Code W | 1000 | Nickle-plated steel |

| Code ST | 1000 | Hardened steel |

| Code B | 1000 | Tempered steel |

| Code CE2 | 1000 | Aluminium ceramic-coated |

| Code ASY | 1000 | Hardcoated aluminium, asymetrical groove Unit without filament guide (not for DTS-200) |

| Code ASYB | 1000 | Tempered steel (for tire code), asymmetrical groove Unit without filament guide (not for DTS-200) |

| Code V1 | 1000 | Hardcoated aluminium (only for DTS-60K-V1) |

| Code U | 2000 | Hardcoated aluminium (radius R3) |

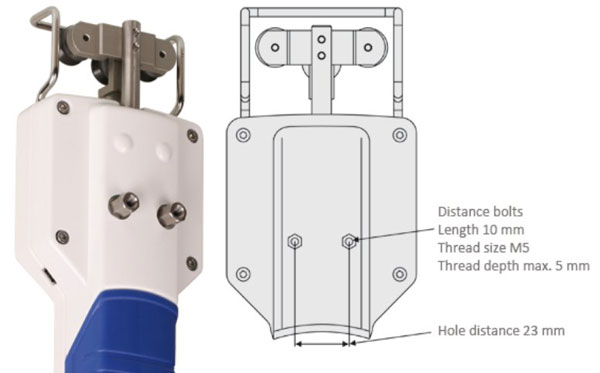

Option MH

for stationary use. With distance bolts with M5 female thread on the rear side.

for stationary use. With distance bolts with M5 female thread on the rear side.

| Accuracy | For PA from 5 % up to 100 % FS*: ± 0.5 % FS* ± 1 digit, remaining tension range and other calibration materials: ±3 % full scale and ±1 digit |

| Memory for material curves | 1 for factory calibration plus 4 for customized calibrations |

| Measuring units | Tension: cN, daN, g, kg, N, lb (user-selected) Thickness : mm, inch (user-selected) |

| Overrange | Approx. 10 % FS*, full scale, without accuracy guarantee |

| Overload protection | 100 % full scale |

| Measuring principle | Strain gauge bridge |

| Measuring roller deflection | Max. 0.2 mm |

| Signal processing | Digital, 16 bit A/D converter |

| Measuring frequency | 1 kHz (1000 samples/sec.) |

| Display | Graphic LCD, Backlit (user-set: on/off/auto) |

| 3 different displays | Numeric, Numeric with graph (time-tension), X-Y-diagram |

| Display update rate | Approx. 2 times per second |

| Memory | Calibration Material, Date/Time of Measurements, MIN, MAX, Hi-PEAK, Lo-PEAK, AVG, LAST and Standard Deviation |

| Damping | User-adjustable electronic damping (averaging) calculated by [X-Values OLD + Y-Values NEW] ÷ 9 |

| Cal. Adjustment | ± 10 steps in 1 % increment |

| Thickness compensation | Max. 2.5 mm (not available for all models) |

| Auto power off | Approx. 3 minutes of non-use |

| Temperature coefficient | Gain: less than ± 0.01 % FS* /°C Zero point: less than ± 0.3 % FS* /°C |

| Temperature range | 10 - 45 °C |

| Air humidity | 85 % RH, max. |

| Power supply | Rechargeable Lithium Polymer Battery provides 40 hours of continuous operation, charging time approx. 3-1/2 hours includes AC-Adapter/Charger 100 – 240 V AC (with EU, USA, UK plug adapter) |

| Housing material | Die-cast aluminium |

| Weight, net (gross) | Up to DTS-50K approx. 875 g / 1550 g DTS-60K-V1 approx. 1040 g / 2700 g |

| Replacement Battery | E08711-X |

| Replacement Charger | USB-MINI-CHARGER |

| Standard Rollers | R50004 |

Thank You

Thank you for your quote request, we will contact you within 1-2 business days.

There was an error submiting the form. Please try again.