Project Process

As an ISO9001:2015 company we have a clear process for custom transducer projects:

- Inquiry

- Qualification of requirement

- Quotation

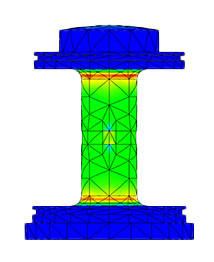

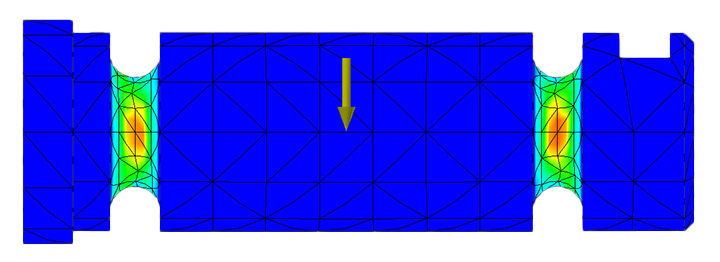

- Design & FEA

- Customer review & sign off

- Materials procurement

- Manufacture and testing

- Dispatch

Since 1977 we have developed data, knowledge and systems to ensure that all SP custom loadcells are accurate, reliable and most importantly safe. With close to 200 load cell products in our catalogue Straightpoint, who are an ISO9001 accredited company, offer a standard product for nearly every application.

However, some applications require specialist solutions and our team of in-house engineers offer a full custom solutions package to assist and project manage any job for which a standard SP product can not be used.

- Custom loadcells for Safety of Lives at Sea (SOLAS) project

- Bespoke 500te wireless compression loadcells for heavy lift industry

- Structural health monitoring project including 40 wireless loadcells in construction industry

- Stainless steel subsea load pins or shear pins manufactured for marine industry

- Custom wireless, multiple loadcell load monitoring package for large entertainment venue

- Approval of wireless custom shear pins to ATEX / IECEx for use in Gas Zones 0, 1 & 2

- Load shackles with digital outputs for topside project

- Development of ATEX / IECEx Gas Zones 0,1 and 2 Radiolink plus

- Custom load cell amplifier design to include 4-20mA output for PLC integration

- In-house strain gauging of client lifting tools

- Wireless load cells linked to a live SMS messaging system to alert nominated users globally of load events

- Dual bridged load cells and load pins for redundancy purposes

Thank You

Thank you for your quote request, we will contact you within 1-2 business days.