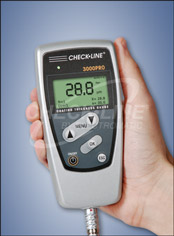

The new Check-Line 3000PRO Series coating thickness gauge is a multifunctional fully menu driven gauge for fast, professional and precise coating thickness measurement for:

- paint and electroplated coatings on iron and steel

- paint and anodizing coatings on non-ferrous metals and on austenitic stainless steels

Eight (6) separate probes are offered for a wide variety of applications.

- Automatic identification of the substrate

- Highly wear-resistant measuring poles made of carbide metal

- Special probes for unusual measurement tasks

- Safe use even for special applications such as sand-blasted surfaces, small parts and curved surfaces

- Scan mode for the quick recognition of coating thickness variations on large surfaces, including display of minimum and maximum readings

- Display backlight for poor ambient lighting conditions

- Online statistics with all statistical parameters

- Extensive memory storage for recording of up to 10,000 data pints in up to 500 separate files "batches"

- Alphanumerical file names can be used to identify each of the separate files "batches"

- Infrared interface for wireless data transfer to printer and PC or via built-in RS-232

- Includes FREE software for transferring data to a PC including histogram function

- Optional high temperature footer for measuring on surfaces up to 150 °C/302 °F

- Includes Traceable Calibration Certificate

- 1 Year Warranty

Probe |

Type |

Range |

| Standard Probes | ||

Fe |

0 – 60 mils (0 – 1500 µm) |

|

NFe |

0 – 60 mils (0 – 1500 µm) |

|

Fe+NFe |

0 – 60 mils (0 – 1500 µm) |

|

| Micro Probe for very thin coatings | ||

Fe+NFe |

0 – 8 mils (0 – 200 µm) |

|

| Probes for thick coatings | ||

Fe |

F: 0 – 140 mils (0 – 3500 µm) N: 0 – 120 mils (0 – 3000 µm) |

|

Fe+NFe |

0 – 140 mils (0 – 3500 µm) |

|

| "F" Probes measure Coatings on Ferrous Metals "N" Probes measure Coatings on Non-Ferrous Metals "FN" Probes measure Coatings on both Ferrous & Non-Ferrous Metals |

||

| Minimum Radius for Convex Surfaces | 0.08" (2 mm) | |

| Minimum Radius for Concave Surfaces | 0.2" (5 mm) | |

| Minimum Headroom | 4" (100 mm) | |

| Minimum Sample Diameter | 0.2" (5 mm) | |

| Minimum Substrate Thickness - F | 8 mils (0.2 mm) | |

| Minimum Substrate Thickness - NFe | 2 mils (50 um) |

| Standard probe & and FN/90° probe | |

| Mils | |

| 0.00 - 9.99 mils | 0.01 mils |

| 10.00 - 24.98 mils | 0.02 mils |

| 25.00 - 49.95 mils | 0.05 mils |

| 50.0 - 99.9 mils | 0.1 mils |

| Microns (µm) | |

| 0.0 - 99.9 µm | 0.1 µm |

| 100.0 - 249.8 µm | 0.2 µm |

| 250.0 - 499.5 µm | 0.5 µm |

| 500 - 999 µm | 1 µm |

| 1.000 - 1.998 mm | 0.002 mm |

| Measuring principle: | Magnetic induction method (F-version); Eddy current method (N-version) |

| Measuring range: | 3000PRO: 0 - 60.00 mils / 0 - 1500 µm |

| Tolerance: | ± (0.7 µm/0.04 mils + 1% of reading) |

| Resolution: | Refer to RESOLUTION TABLE, above |

| Display: | 4-digit display (digit height 10 mm/0.4") and 32 alphanumerical characters; switchable backlight |

| Minimum measurement area: | 5 mm x 5mm/0.2" x 0.2" |

| Minimum curvature radius: | convex 2mm/0.08"; concave 5mm/0.2" |

| Minimum substrate thickness: | 0.2mm/8 mils (for F-versions); 50 µm/2 mils (for N-versions) |

| Calibration methods: | - Factory calibration: no calibration required for standard applications - Zeroing (1-point calibration): measurements on small geometries - Zeroing and foil calibration (2-point calibration): increased measuring accuracy - Two-foil calibrat |

| Limit values: | Selectable; optical and acoustic signal if limit value is exceeded |

| Scan mode: | For continuous measurements; for the quick recognition of coating thickness variations; with permanent display of minimum and maximum reading |

| Statistics: | Single-value statistics: n, avarage x, s, kvar, min, max, cp, cpk from max. 10,000 readings Block-value statistics: n, avarage x , avarage s, avarage kvar , min, max, cp, cpk; block size 3 to 100 readings |

| Data memory: | 10,000 readings in max. 500 selectable files; alphanumerical file names; stored readings and statistical values individually recallable |

| Interfaces: | Infrared and serial RS232 interface |

| Language: | Operator prompting and documentation in German, English, French (optional other languages) |

| Operating temperature: | 0 °C to 50 °C/32 °F to 122 °F (storage temperature - 20 °C to +60 °C/-4 °F to 140 °F) |

| Surface temperature: | 5° F - 140° F / -15° C - 60° C (standard) 5° - 302° F / 15° - 150° C (w/3000-HTF) 5° - 572° F / 15° - 300° C (w/3000-HTF-300C) |

| Power supply: | 2 x round cell (AA) 1.5 V up to 60 hours of operating time |

| Housing/keypad: | Protection class IP52 (protection against dust and dripping water) |

| Dimensions: | Gauge: 140 mm x 62 mm x 30mm/5.6" x 2.5" x 1.2" (HxWxD) Probe: dia. 14 mm x 83mm/dia. 0.56" x 3.3" |

| Weight: | approx. 200 g/7 oz (gauge including batteries and probe) |

| Standards: | DIN EN ISO, ASTM, BS |

| Warranty | 1 Year |

| Calibration Certificate | Included |

| Item | Description | Price | ||

|---|---|---|---|---|

Coating Thickness Display, Probes Sold SEPARATELY | $1,295.00 | |||

| Accessories | ||||

Ferrous Only Probe (60 mils/1500 microns) | $345.00 | |||

Non-Ferrous Only Probe (60 mils/1500 microns) | $345.00 | |||

Ferrous & Non-Ferrous Only Probe (60 mils/1500 microns) | $695.00 | |||

Ferrous & Non-Ferrous Probe (8 mils/200 microns) | $995.00 | |||

Ferrous Only Probe (140 mils/3500 microns) | $895.00 | |||

Ferrous & Non-Ferrous Probe (140 mils/3500 microns) | $1,095.00 | |||

3000-HTF | High Temp Footer for 3000FX / 3000PRO. 300° F / 150° C Limit | $75.00 | ||

3000-HTF-300C | High Temp Footer for 3000FX / 3000PRO. 572° F / 300° C Limit - Please contact us for pricing and availability. | $ | ||

Coating Thickness Gauge Probe Stand | $740.00 | |||

USB-RS232-ADAP | RS232 to USB Adapter | $25.00 | ||

In stock

1 Week Lead Time (Estimated)

2-3 Week Lead Time (Estimated)

Lead Time Varies, Please contact us for availability.

Unavailable