Several ranges available

Several ranges available 10N / 0 to 50N / 11 Lbs (ULR - Ultra Low Range)

0 to 100N / 22 Lbs up to 0 to 500N / 110 Lbs (LR - Low Range)

0 to 1kN / 220 Lbs (Standard Range)

0 to 2kN / 440 Lbs up to 0 to 3kN / 660 Lbs (HR - High Range)

Material Diameters - 0.1 - 5.5 mm (0.004" - 0.217")

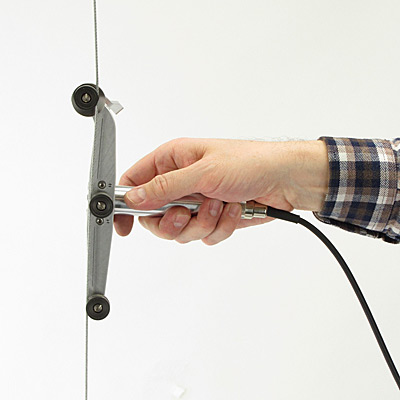

The 136-3-SCF-DC is especially-designed for use in Closed Force System (CFS) applications, where both ends of the material are fixed. This sensor is designed so the cable will pass under the 1st roller and over the center and last roller. This design applies a minimal break angle of the material over the center sensing roller minimizing the error caused by the presence of the tension sensor.

With traditional 3-Roller systems where the material travels under/over the rollers in the illustration above, a significant error is generated by the presence of the tension sensor increasing the tension dramatically --- as soon as the sensor is installed. The unique design concept of 136-3-SCF-DC eliminates this problem and provides the only accurate means of measuring tension in these types of applications.

The accuracy of this sensor is further enhanced by its built-in diameter compensator adjustment. The operator simply adjusts the diameter compensator to equal the diameter of the process material being measured and the calibration is automatically adjusted for highest accuracy. The typical measuring error is less than 1%.

The sensor 136-3-SCF-DC for the first-time enables engineers and maintenance personnel the possibility to measure tension in closed force systems including:

- Yarns & Filaments

- Brake Cables

- Aircraft Cables

- Architectures Cables

- Wires/Cables up to 5mm diameter

- Built-in Diameter Compensator for material diameters 0.1 - 5.5 mm (0.004" - 0.217")

- Minimal sensor influence on the tension by utilizing the smallest deflection angle possible

- High accuracy and reproducibility

-

Small angle of material bending, therefore

- No damage of the material

- Very low additional tension during measurement - 190 mm clearence required along the length of the process material to place tension meter

Tension Measurement:

- Thin stay ropes and cables

- Thin static wires

- Thin pre-loaded wire ropes, steel wire ropes

- Aircraft support cables

- Overhead cables

- String tension of musical instruments

- Wire EDM machines

- Airplane manufacturing

Thank You

Thank you for your quote request, we will contact you within 1-2 business days.

There was an error submiting the form. Please try again.