Stationary electronic tension sensor, single roller system, for mounting at an existing deflection pulley

Large, hardened guide rollers for minimized material deflection with 29.5 mm groove ⌀

Tension meter is available with digital output for data processing with PC

Large, hardened guide rollers for minimized material deflection with 29.5 mm groove ⌀

Tension meter is available with digital output for data processing with PC

- V-grooved guide rollers, ball-bearing mounted

- Tension sensor with integrated measuring amplifier

- Various output signals: analog, digital (optional), current (optional), analog DMS (optional)

- Many configurations are possible

- Easy calibration to customized material by operator

- Tension sensor with mechanical overload protection

- Wide variety of roller types can be specified

- Guide rollers 30 or 70 mm ⌀, made of Aluminium or steel

- In- and outcoming angle β min 20°

- Rugged aluminium housing

- Certificate of Compliance with the order 2.1 according EN 10204 is included

- Optionally available: Inspection Certificate 3.1 according EN 10204 with calibration report

| Model | Resultant Force Capacity (g/Kg) | Resultant Force Capacity (Newtons) |

|---|---|---|

| TSR-10N | 1000 grams | 10 N |

| TSR-20N | 2000 grams | 20 N |

| TSR-50N | 5 Kg | 50 N |

| TSR-100N | 10 Kg | 100 N |

| TSR-200N | 20 Kg | 200N |

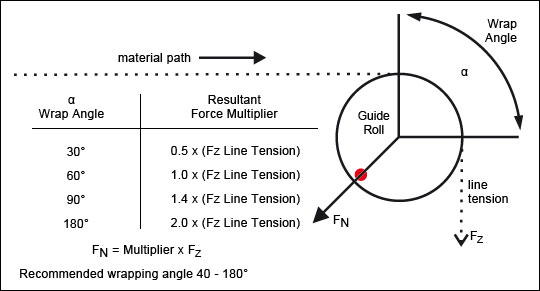

The tension range can be calculated for every wrapping angle with this formula:

FN = Nominal load (Multiplier * FZ)

FZ = Line Tension

α = Wrapping angle at the guide roll

FN = 2 * FZ * sin( α/2 )

When selecting the nominal measurement force it is necessary to take into account the weight of the guide roll and raise the nominal load respectively, particularly when working with small nominal forces.

| Order Code | Line Speed Vmax ...m/min | Roller Material |

|---|---|---|

| Standard | 4000 | Hardened steel |

| Code F | 4000 | Hard-coated aluminium |

| Code FB | 4000 | Tempered steel |

| Accuracy | factory calibration material: ±1 % full scale and ±1 digit other calibration material: ±3 % full scale or better |

| Overload protection | 100 % of tension range |

| Measuring principle | Strain gauge bridge |

| Measuring roller deflection | Max. 0.5 mm |

| Natural frequency | Approx. 500 Hz, depending on tension range |

| Signal processing | Analog (option: digital) |

| Temperature drift | Less than ±0.05 % full scale/°C |

| Output signal | Standard: 0 - 1 V DC (analog) impedance: ≥ 5 kΩ Option: 0 - 10 V DC (analog), 4 - 20 mA (current) or mV/V (DMS) digital RS 232 |

| Damping (fg) | Standard: 30 Hz (other values on request) |

| Temperature range | 10 - 45 °C |

| Air humidity | 85 % RH, max. |

| Power supply | +15...24 V DC, max. 50 mA regulated Code A10: max. +5 V DC, max. 20 mA regulated |

| Housing material | Aluminium |

| Weight, net (gross) | Approx. 250 g (approx. 400 g) |