Heavy-Duty Tension Sensor wires, cables, tirecord and similar process materials.

Heavy-Duty Tension Sensor wires, cables, tirecord and similar process materials.

7 tension ranges from 0 - 1000 g to 0 – 100 kg Newly-designed tension sensor accurately measures the running tension of wires, cables, tirecord, plastic tubing and similar process materials up to 8 mm diameter (0.300"). Fitted with 29.5 mm diameter V-Grooved rollers fabricated from stainless steel are suitable for material speeds up to 4000 meters/min. Built-in signal conditioning with ZERO and SPAN pots provide a high-level, analog output to minimize the chance for signal interference.

Can be using for process diagnostics, for continuously monitoring and recording of online tensions. The TS2 Tension Sensor can also be used as part of a closed-loop control system with 3rd-Party controller.

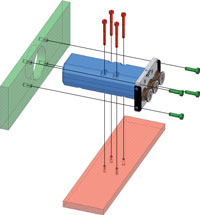

Mounting possibilities: Sensor can be mounted on a flat plate using the supplied thru holes in the housing body or fixed using the holes in the front plate, inserted thru a round hole in machine frame or plate.

- Strain Gauge-based sensor provides accuracy of 1.5% Full Scale or better. Sensor can be mounted in any orientation depending upon the material path.

- Built-in Signal Conditioner provides 0-1 V DC Analog Output with Integrated Zero & Gain Pots on rear-side of sensor allowing for convenient calibration by the end-user for highest accuracy

- Optional output types include 0-10V DC, 4-20mA, RS-232, USB or WiFi

- 29.5 mm diameter Ball-Bearing mounted V-grooved guide rollers are fabricated from Stainless Steel. Optional roller types can be specified including U-Grooved, Flat Groove and more

- Cast Aluminum Housing is rugged and proves for easy installation using thru holes in housing body or front plate

- Can be used together with SC-PM Digital Tension Indicator or with user-supplied electronics (requires 15-24 V DC regulated power).

- 3-Roller design insures that the center sensor rollers has the same wrap angle at all times which allows the sensor to be mounted in any position on the line

- Outer roller spacing changes from 100 mm for ranges up to 5 Kg, to 150 mm for ranges up to 10Kg and 200 mm for ranges up to 50Kg.

- Custom-designs are possible along with special features such as air fitting to create positive internal pressure in the housing for protection against airborne chemicals or contaminants

| Model | Range | *Measuring Head Width | **Calibration Material |

|---|---|---|---|

| TS2H-1K | 0 - 1000 g or cN | PA: 0.30 mm Ø | |

| TS2H-2K | 0 - 2000 g or cN | PA: 0.50 mm Ø | |

| TS2H-5K | 0 - 5 kg or daN | PA: 0.80 mm Ø | |

| TS2H-10K | 0 - 10 kg or daN | PA: 1.00 mm Ø | |

| TS2H-20K | 0 - 20 kg or daN | PA: 1.50 mm Ø | |

| TS2H-50K | 0 - 50 kg or daN | Steel rope 1.50 mm Ø (7x7x0.20) | |

| TS2H-100K | 0 - 100 kg or daN | Steel rope 3.00 mm Ø (6x7x0.30) |

Other tensions ranges and measuring head widths available on request.

* Outside dimensions of front plate

** Suitable for 95 % of applications

PA = Polyamide Monofi lament

Custom Calibration to Customer Sample

If the process material differs significantly from the Factory Calibration Material in diameter, rigidity or shape, a special calibration using a customer-supplied sample is recommended. For this purpose, a sample of about 5 meters (15 Ft) should be supplied.

** Suitable for 95 % of applications

PA = Polyamide Monofi lament

Custom Calibration to Customer Sample

If the process material differs significantly from the Factory Calibration Material in diameter, rigidity or shape, a special calibration using a customer-supplied sample is recommended. For this purpose, a sample of about 5 meters (15 Ft) should be supplied.

| Standard | 0 - 1 V DC (analog) |

| Option | Code DC: 0 - 10 V DC |

| Option | Code MA: 4 - 20 mA |

| Option | USB: USB |

| Option | Code 232: RS-232 |

| Option | Code 422: RS-422 |

| Accuracy | ± 1.5% full scale and ±1 digit % full scale or better Other calibration material: ±3 % full scale or better |

| Overload Protection | 100% of tension range (200% total) |

| Measuring Principle | Strain guage bridge |

| Meas. Roller Defelction | 0.5 mm, max |

| Output Signal | Standard: 0 - 1 V DC (analog) Option DC: 0 - 10 V DC Option MA: 4-20 mA Option 232: RS-232 |

| USB Output (Option "-USB) | USB Connection direct to Windows PC (requires TensionInspect Software, SW-TI3) Supplied with 3 meter USB-A to USB-B Cable. If USB Cable longer than 5 meters is required, a USB Signal Booster is required. |

| Option "A10" Strain Gauge Output | 0.6 +/- 0.12 mV / V, 5V DC (max) power required (3-5V DC) |

| Frequency Response | 30Hz (custom frequency response up to 100 Hz available as an option) |

| Temperature Drift | Less than ± 0.1% Full Scale / °C |

| Temperature Range | 10 - 45 °C |

| Air Humidity | 85% RH, max |

| Power Required | +15 ... 24 V DC, 50 mA (regulated) |

| Housing Material | Aluminum |

| Weight | Approx. 500 g |

| Connection to PD765 | SIGNAL:Grey (Sig+) to V+, Blue (Sig-) to COM DC-POWER: White (Exc+) to P2+, Black/Brown (Exc-) to P2- |

Thank You

Thank you for your quote request, we will contact you within 1-2 business days.

There was an error submiting the form. Please try again.