3 Models available

TIME5100 - Standard model with integrated impact device D

TIME5102 - Special model for Hardness Measurement on surface hardened components, coatings, thin walled components. It has app. 1/4 impact energy of TIME5100/TIME5104. Integrated impact device C.

TIME5104 - Special model for Hardness Measurement in extremely confined spaces. Integrated impact device DL.

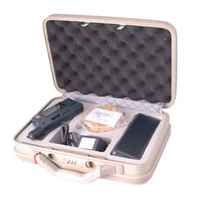

The small portable TIME5100 hardness testers with integrated impact device are designed for an extremely wide range of applications. They are especially recommended for Hardness Measurement on the shop floor. The automatic identification of the impact test direction makes them easy to use. Hardness tests are possible at any angle, even upside down. The data memory stores up to 270 values. Data can be transferred via USB interface to a computer or printer.

The outstanding features of the TIME5100 includes speedy and exceptionally user-friendly operation and high measuring accuracy, with an extremely low tolerance of ± 1.5%.

The hardness tester functions by releasing a small impact device on to the metal testing surface by means of a spring mechanism. The gauge's dynamic measuring procedure works by calculating the difference between the impact velocity and the rebound velocity of impact device.

The TH-170 can be used on a whole variety of metals. A statistics program calculates the mean hardness value from a number of single readings. Readings can be printed out immediately on a mini-printer or stored for later processing.

Hardness Measurement on metal substances such as:

Steel, cast steel, cold work tool steel, stainless steel, grey/nodular cast iron, aluminium, cast aluminium alloys, brass, bronze and wrought copper alloys

TIME5100 - Standard model with integrated impact device D

TIME5102 - Special model for Hardness Measurement on surface hardened components, coatings, thin walled components. It has app. 1/4 impact energy of TIME5100/TIME5104. Integrated impact device C.

TIME5104 - Special model for Hardness Measurement in extremely confined spaces. Integrated impact device DL.

The small portable TIME5100 hardness testers with integrated impact device are designed for an extremely wide range of applications. They are especially recommended for Hardness Measurement on the shop floor. The automatic identification of the impact test direction makes them easy to use. Hardness tests are possible at any angle, even upside down. The data memory stores up to 270 values. Data can be transferred via USB interface to a computer or printer.

The outstanding features of the TIME5100 includes speedy and exceptionally user-friendly operation and high measuring accuracy, with an extremely low tolerance of ± 1.5%.

The hardness tester functions by releasing a small impact device on to the metal testing surface by means of a spring mechanism. The gauge's dynamic measuring procedure works by calculating the difference between the impact velocity and the rebound velocity of impact device.

The TH-170 can be used on a whole variety of metals. A statistics program calculates the mean hardness value from a number of single readings. Readings can be printed out immediately on a mini-printer or stored for later processing.

Hardness Measurement on metal substances such as:

Steel, cast steel, cold work tool steel, stainless steel, grey/nodular cast iron, aluminium, cast aluminium alloys, brass, bronze and wrought copper alloys

- Portable dynamic metal hardness testing set

- Automatic identification of impact test direction

- Memory up to 270 average readings in 9 freely selectable files

- Automatic power off

- Data output USB

- Integrated impact device: no cables

- Direct display of hardness values in Rockwell HRB, Rockwell HRC, Vickers HV, Brinell HB, Shore HS and Leeb HLD

- Test at any angle, even upside down

- For nearly all metals

- Upper and lower limit setting

- Large LCD with backlight

- Calibration feature

- Large, heavy components or fixed machine parts

- Serial products during the production process

- Material identification in storage

- Measurement on locations with difficult access

- Minimum measuring area 10 mm x 10 mm

- Minimum curvature radius r of the measuring area, 30 mm, without adapter.

- Minimum curvature radius with screw-on V-adapter, 11mm.

- Samples weighing less than 5 kg and samples less than 5 mm thickshould be placed on a solid base to prevent vibration.

- Samples weighing less than 2 kg should be fixed to a solid base withcoupling paste.

| TIME5100 | |

|---|---|

| Impact device | D (standard) integrated |

| Workpiece radius (convex/concave) | Rmin = 50mm (with support ring Rmin = 10mm) |

| Workpiece maximum weight | 2kg on solid support (0.1kg with couplant paste) |

| Workpiece min. thickness coupled | 3mm |

| Workpiece min. case hardened depth | 0.8mm |

| TIME5102 | |

| Impact device | C integrated |

| Workpiece radius (convex/concave) | Rmin = 50mm (with support ring Rmin = 10mm) |

| Workpiece maximum weight | 0.5kg on solid support (0.02kg with couplant paste) |

| Workpiece min. thickness coupled | 1mm |

| Workpiece min. case hardened depth | 0.2mm |

| TIME5104 | |

| Impact device | DL integrated |

| Workpiece radius (convex/concave) | Rmin = 10mm |

| Workpiece maximum weight | 2kg on solid support (0.1kg with couplant paste) |

| Workpiece min. thickness coupled | 3mm |

| Workpiece min. case hardened depth | 0.8mm |

| General Information | |

| Hardness scales | HRC, HRB, HB, HV, HS, HLD |

| Measuring range | HLD 200 to 900 HRB 13 to 100 HRC 20 to 68 HB 20 to 655 HV 80 to 950 HS 32 to 100 |

| Accuracy | ± 6HLD (for HLD approx. 800) |

| Measuring direction | 0° - 360° |

| Memory | 270 average readings in 9 freely selectable files |

| Interface | USB 2.0 |

| Standard impact device | Type D, integrated |

| Max. surface roughness of workpiece | 1.6 µm Ra |

| Max. workpiece hardness | 900 HLD |

| Min. workpiece radius (convex/concave) | Rmin = 50mm (10mm with support ring) |

| Min. workpiece weight | 2kg on stable support, 0.1kg with coupling paste |

| Min. workpiece thickness coupled | 3mm with coupling paste |

| Min. thickness of hardened layers | 0.8mm |

| Power supply | AAA 1.5V batteries (2 pcs) |

| Operating temperature | 0° - 40°C |

| Dimensions | 150 mm x 55 mm x 25 mm |

| Weight | 165 g |

| Item | Description | Price | ||

|---|---|---|---|---|

TIME5104 | Dynamic hardness tester with integrated impact device DL (formerly TH-174) | $2,080.00 |

In stock

1 Week Lead Time (Estimated)

2-3 Week Lead Time (Estimated)

Lead Time Varies, Please contact us for availability.

Unavailable