The PosiTest® LPD Low voltage Pinhole Detector detects holidays, pinholes and other discontinuities on metal and concrete substrates.

- Easy-to-use interface with bright, multi-function LEDs

- Ready to measure - both kits come with everything needed for testing

- Audibly and visibly alerts when flaws are detected

- Lightweight, ergonomic design

- Rugged, environmentally sealed enclosure

- Weatherproof, dustproof and shockproof - meets or exceeds IP65

- Two year warranty

- Automatic self-test verifies voltage calibration

- Regulated voltage outputs will not drop under load

- Long Form Certificate of Calibration included

- GroundSense™ visibly reassures the user that the instrument is properly grounded

- Conforms to international standards including ISO, ASTM and NACE

- A wide range of adaptable sponge hardware for a variety of test configurations

- Common threads and connectors allow for maximum flexibility

- Headphone jack with included earbud for noisy environments

- Uses 3 AAA alkaline or rechargeable batteries

- 4 voltage output options conform to a variety of standards

PosiTest® LPD Basic Kit

Basic Kit comes complete with PosiTest LPD, base tube, 3 AAA batteries, rectangle sponge hardware, rectangle sponge, 4.5 m (15’) ground wire, insulating collar, ear bud, wrist strap, carabiner, Long Form Certificate of Calibration traceable to NIST, instructions, hard shell case, two year warranty

Basic Kit comes complete with PosiTest LPD, base tube, 3 AAA batteries, rectangle sponge hardware, rectangle sponge, 4.5 m (15’) ground wire, insulating collar, ear bud, wrist strap, carabiner, Long Form Certificate of Calibration traceable to NIST, instructions, hard shell case, two year warranty

PosiTest® LPD Complete Kit

Includes contents of the Basic Kit, plus adaptable sponge hardware and extension accessories in a hardshell case.

Includes contents of the Basic Kit, plus adaptable sponge hardware and extension accessories in a hardshell case.

Adaptable Sponge Hardware

- Rectangle (Flat)

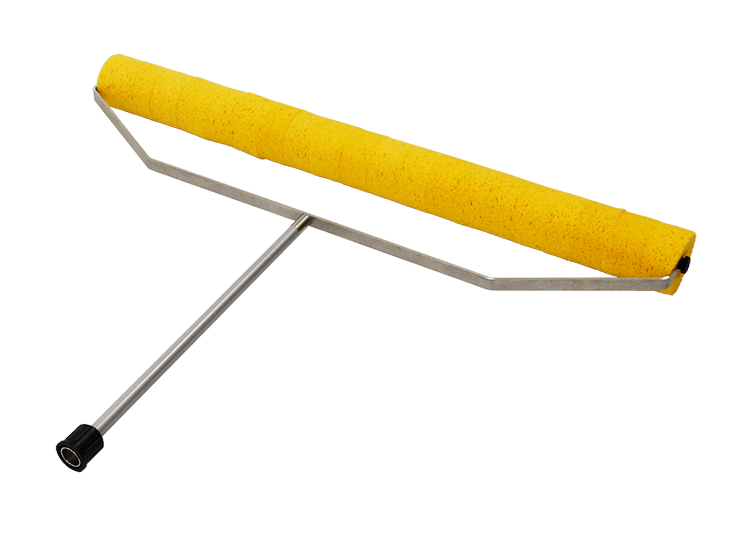

- Roller

- Internal Diameter

- Additional 20 cm x 20 cm (8" x 8") sheet sponge for custom usages

- Wetting agent

- Extension rods provide an additional 0.6 m (2') of reach

- Universal adapters to extend existing paint rollers and poles

- 12 m (40') ground wire

- 4.5 m (15') hot wire

- Magnetic grounding post

Quick inspection over large areas

New! Large Roller Sponge (610 mm/24") for the PosiTest LPD. | LPDWANDR24

| Voltage | 9V ± 5% | 67.5V ± 5% | 67.5V ± 5% | 90V ± 5% |

|---|---|---|---|---|

| Sensitivity | 90k ± 3% | 80k ± 3% | 90k ± 3% | 400k ± 3% |

| Thickness Range | 0 - 500 µm (0 - 20 mils) | |||

| Temperature Range | -10 - 50° C (14 - 122° F) | |||

| Battery Life | > 150 hrs (depending on battery type) | |||

| IP Rating | meets or exceeds IP65 | |||

| Size | 27 x 6 x 5.5 cm (10.6" x 2.3" x 2.1") without wand | |||

| Weight | 180 g (6.4 oz.) without batteries | |||

| Conforms to ISO 14654, ISO 8289-A, ASTM G62, G6, D5162, DS7793-2, NACE TM0384, SP0188, AS3894.2, JIS K 6766 | ||||

What is a pinhole detector?

A pinhole detector is a non‐destructive instrument for detecting discontinuities in a coating system including pinholes, cracks and thin spots. Other names include porosity detector, continuity tester, sponge tester and holiday detector.

There are two types of pinhole detectors, low voltage (wet sponge) and high voltage (spark tester). Low voltage detectors, like the PosiTest LPD, are typically used on coating systems less than 500 µm (20 mils) thick. High voltage spark testers operate at voltages up to 35,000V which can seriously harm the operator and damage the coating if the test is not correctly conducted. They tend to be more expensive and more complex than low‐voltage pinhole detectors.

What is measured with a low-voltage pinhole detector?

A low‐voltage pinhole test is performed by moving a moistened, electrified sponge over a non‐conductive coating applied to a conductive substrate. The instrument is‘grounded’ or ‘earthed’ to the conductive substrate, typically by clamping onto an uncoated area. When the coating is continuous and no defects are present, electricity is unable to pass from the sponge to the substrate through the non‐conductive coating. But when the electrified sponge encounters a flaw in the coating, electricity is able to flow into the substrate and travel back to the instrument through the ground wire, completing the circuit and setting off the audible and visible alarms.

Why is porosity measurement important?

After a protective coating has been applied, it is important to ensure there are no defects or discontinuities present that expose the substrate beneath. Small areas of thin or missing coating, called ‘pinholes’ or ‘holidays’, can become foci for corrosion and drastically reduce the life of a protective coating system. They can be invisible to the naked eye. Porosity detectors are often used in applications where corrosion is difficult to monitor, or in aggressive service environments where performance of the protective coating is critical.

How does a low-voltage pinhole detector measure coatings on concrete?

When measuring coating thickness, concrete is not considered a ‘conductive’ substrate, as it is much less conductive than metal. However, concrete is still slightly conductive, and can carry enough current to allow low‐voltage pinhole detectors to function. Therefore, for the purposes of low‐voltage pinhole detection, concrete is considered a ‘conductive’ substrate.

The challenge when conducting low‐voltage pinhole testing on concrete is to ensure the instrument is properly grounded. If there is exposed rebar or metal protruding from the concrete, this is the easiest solution. An alternative is to drive a metal rod (or piece of rebar) into the ground nearby the concrete to at least the depth of the slab, relying on the earth to conduct the electric current between the rod and the slab.

How is the PosiTest® LPD different than other pinhole detectors?

The PosiTest LPD has been designed as a fully customizable unit and offers a number of features not typically found in other competitive instruments.

-Lightweight – weighs less than most competitive products, reducing muscle strain and fatigue

-Ergonomic design ‐‐while most other devices are box‐shaped, the PosiTest LPD was specifically designed to fit comfortably in the hand with a balanced weight distribution

-Easy‐to‐use – bright LEDs and simple 3‐button operation with graphic icons

-Calibrated (well‐regulated) voltage outputs that will not drop under load. The PosiTest® LPD is more likely to find small pinholes than other devices.

-GroundSense™ visibly reassures the user that the instrument is properly grounded. Users of most competitive devices would not alert if the connection to ground is lost, resulting in undetected pinholes.

-Common threads and connectors that allow for unprecedented compatibility and customization. Customers can extend the reach of the PosiTest LPD with their own poles and extension rods.

-All models include a hard shell case to conveniently carry the instrument and all accessories.

-Includes Long Form Certificate of Calibration traceable to NIST

-Two year warranty

-IP65 ingress protection‐ dust and splash resistant. No other device is rated this highly.

What is the purpose of a wetting agent?

Sometimes pinholes are so miniscule that water has difficulty reaching the conductive substrate underneath, especially on thicker coatings when the water must penetrate further into a pinhole to reach the substrate. In these instances, inspectors will use a surfactant (wetting agent) to lower the surface tension of the water, allowing the solution to better penetrate the pinhole.

Is the PosiSoft® LPD compatible with Posisoft solutions?

No. The PosiTest® LPD does not record any data.

How is the PosiTest® LPD calibrated?

Each PosiTest® LPD is calibrated at all test voltages with a load of known electrical resistance and a voltmeter, each traceable to a National Metrology Lab. A Long Form Certificate of Calibration containing actual measured values is included with every instrument. No other device provides this level of Certification.

What is the recertification cost for the PosiTest LPD?

The cost to recertify is $95 and includes a Long Form Certificate of Calibration. Recertification usually takes one day.

Do your instruments require any formal training for use? Do you offer ‘demo’ models?

No. Our instruments are designed for simple operation, feature easy-to-use menus, both full and quick instruction manuals, and helpful videos. In lieu of demonstration models, we provide unlimited technical support via telephone and/or email, and a limited 30-day money back guarantee.

Is the PosiTest LPD calibrated at the factory?

The PosiTest LPD arrives fully calibrated and ready to measure. A Long-Form Certificate of Calibration traceable to NIST or PTB is included, which documents actual readings taken by your instrument at our calibration laboratory on standards traceable to a national metrology institute.

No other device provides this level of Certification. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements.

A pinhole detector is a non‐destructive instrument for detecting discontinuities in a coating system including pinholes, cracks and thin spots. Other names include porosity detector, continuity tester, sponge tester and holiday detector.

There are two types of pinhole detectors, low voltage (wet sponge) and high voltage (spark tester). Low voltage detectors, like the PosiTest LPD, are typically used on coating systems less than 500 µm (20 mils) thick. High voltage spark testers operate at voltages up to 35,000V which can seriously harm the operator and damage the coating if the test is not correctly conducted. They tend to be more expensive and more complex than low‐voltage pinhole detectors.

What is measured with a low-voltage pinhole detector?

A low‐voltage pinhole test is performed by moving a moistened, electrified sponge over a non‐conductive coating applied to a conductive substrate. The instrument is‘grounded’ or ‘earthed’ to the conductive substrate, typically by clamping onto an uncoated area. When the coating is continuous and no defects are present, electricity is unable to pass from the sponge to the substrate through the non‐conductive coating. But when the electrified sponge encounters a flaw in the coating, electricity is able to flow into the substrate and travel back to the instrument through the ground wire, completing the circuit and setting off the audible and visible alarms.

Why is porosity measurement important?

After a protective coating has been applied, it is important to ensure there are no defects or discontinuities present that expose the substrate beneath. Small areas of thin or missing coating, called ‘pinholes’ or ‘holidays’, can become foci for corrosion and drastically reduce the life of a protective coating system. They can be invisible to the naked eye. Porosity detectors are often used in applications where corrosion is difficult to monitor, or in aggressive service environments where performance of the protective coating is critical.

How does a low-voltage pinhole detector measure coatings on concrete?

When measuring coating thickness, concrete is not considered a ‘conductive’ substrate, as it is much less conductive than metal. However, concrete is still slightly conductive, and can carry enough current to allow low‐voltage pinhole detectors to function. Therefore, for the purposes of low‐voltage pinhole detection, concrete is considered a ‘conductive’ substrate.

The challenge when conducting low‐voltage pinhole testing on concrete is to ensure the instrument is properly grounded. If there is exposed rebar or metal protruding from the concrete, this is the easiest solution. An alternative is to drive a metal rod (or piece of rebar) into the ground nearby the concrete to at least the depth of the slab, relying on the earth to conduct the electric current between the rod and the slab.

How is the PosiTest® LPD different than other pinhole detectors?

The PosiTest LPD has been designed as a fully customizable unit and offers a number of features not typically found in other competitive instruments.

-Lightweight – weighs less than most competitive products, reducing muscle strain and fatigue

-Ergonomic design ‐‐while most other devices are box‐shaped, the PosiTest LPD was specifically designed to fit comfortably in the hand with a balanced weight distribution

-Easy‐to‐use – bright LEDs and simple 3‐button operation with graphic icons

-Calibrated (well‐regulated) voltage outputs that will not drop under load. The PosiTest® LPD is more likely to find small pinholes than other devices.

-GroundSense™ visibly reassures the user that the instrument is properly grounded. Users of most competitive devices would not alert if the connection to ground is lost, resulting in undetected pinholes.

-Common threads and connectors that allow for unprecedented compatibility and customization. Customers can extend the reach of the PosiTest LPD with their own poles and extension rods.

-All models include a hard shell case to conveniently carry the instrument and all accessories.

-Includes Long Form Certificate of Calibration traceable to NIST

-Two year warranty

-IP65 ingress protection‐ dust and splash resistant. No other device is rated this highly.

What is the purpose of a wetting agent?

Sometimes pinholes are so miniscule that water has difficulty reaching the conductive substrate underneath, especially on thicker coatings when the water must penetrate further into a pinhole to reach the substrate. In these instances, inspectors will use a surfactant (wetting agent) to lower the surface tension of the water, allowing the solution to better penetrate the pinhole.

Is the PosiSoft® LPD compatible with Posisoft solutions?

No. The PosiTest® LPD does not record any data.

How is the PosiTest® LPD calibrated?

Each PosiTest® LPD is calibrated at all test voltages with a load of known electrical resistance and a voltmeter, each traceable to a National Metrology Lab. A Long Form Certificate of Calibration containing actual measured values is included with every instrument. No other device provides this level of Certification.

What is the recertification cost for the PosiTest LPD?

The cost to recertify is $95 and includes a Long Form Certificate of Calibration. Recertification usually takes one day.

Do your instruments require any formal training for use? Do you offer ‘demo’ models?

No. Our instruments are designed for simple operation, feature easy-to-use menus, both full and quick instruction manuals, and helpful videos. In lieu of demonstration models, we provide unlimited technical support via telephone and/or email, and a limited 30-day money back guarantee.

Is the PosiTest LPD calibrated at the factory?

The PosiTest LPD arrives fully calibrated and ready to measure. A Long-Form Certificate of Calibration traceable to NIST or PTB is included, which documents actual readings taken by your instrument at our calibration laboratory on standards traceable to a national metrology institute.

No other device provides this level of Certification. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements.

| Item | Description | Price | ||

|---|---|---|---|---|

PT-LPDKITC | PosiTest LPD Low voltage Pinhole Detector Complete Kit - LPDKITC | $1,245.00 | ||

| Accessories | ||||

LPDACCPK | PosiTest LPD Accessory Pack- convert the PosiTest LPD Basic Kit into a PosiTest LPD Complete Kit. | $765.00 | ||

LPDCBLDWAND | PosiTest LPD Cabled Wand | $60.00 | ||

LPDWANDR | Replaceable round sponges and roller wand attachment | $85.00 | ||

LPDWANDR24 | Roller Sponge Wand 610mm/24" | $175.00 | ||

LPDSPONGESPK | Rectangular Sponges (3) | $15.00 | ||

LPDSPONGERPK | Roller Sponges (12) | $30.00 | ||

LPDSPONGECPK | 8" x 8" Custom Sponges (3) | $25.00 | ||

LPDSPONGE18 | 18" x 18" Custon Sponge (1) | $60.00 | ||

LPDEXTROD | Extension Rod (305 mm) | $60.00 | ||

LPDWET | 60 ml Wetting Agent (2) | $25.00 | ||

LPDVERIFY | PosiTest LPD Verifier | $685.00 | ||

In stock

1 Week Lead Time (Estimated)

2-3 Week Lead Time (Estimated)

Lead Time Varies, Please contact us for availability.

Unavailable