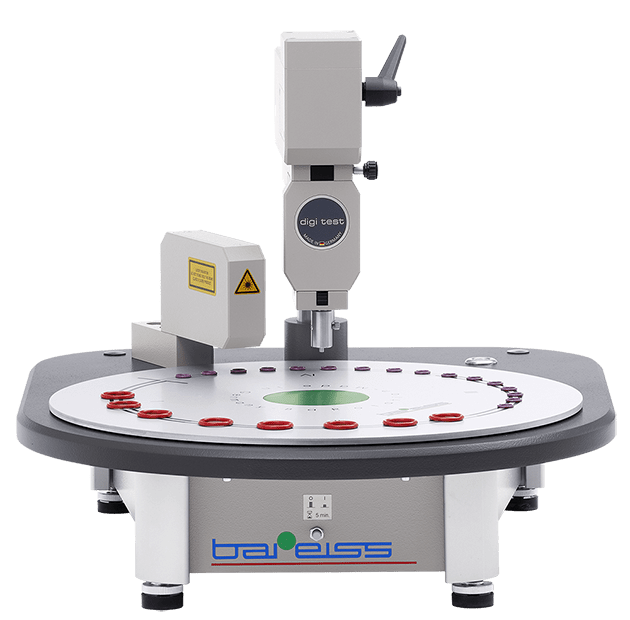

BaRotation has successfully improved the testing capacity of the instrument through the automatic turntable and positioning by measuring the time and procedures required for a single product. It is equipped with a high-performance laser module to accurately locate the highest point or middle point of the O-ring, and then The O-ring is automatically taken to the hardness test area for testing by laser positioning. All procedures are suitable for small batch and multi-style testing needs. Hardness determination on soft rubber, highly elastic materials, soft deformable materials (e.g., thin-wall O-Rings).

- Time saving

- Automatic evaluation

- Batch dependent settings

- Descending speed of ⅛"/s

| Range of application | Hardness determination on soft rubber, highly elastic materials, soft deformable materials (e.g. thin-wall O-Rings) |

| Standards | DIN ISO 48, ASTM D 1415, NFT 46-003, BS903 Part. A 26 |

| Measuring principle | IRHD Mikro | M Shore A The indenter of the instrument penetrates the specimen from the surface. This indentation depth provides the hardness information of the test specimen. |

| Memory | Memory for 300 measured values |

| Plug-in power supply | 100-240V; 50-60 Hz |

| Data output | RS 232 (Serial) |

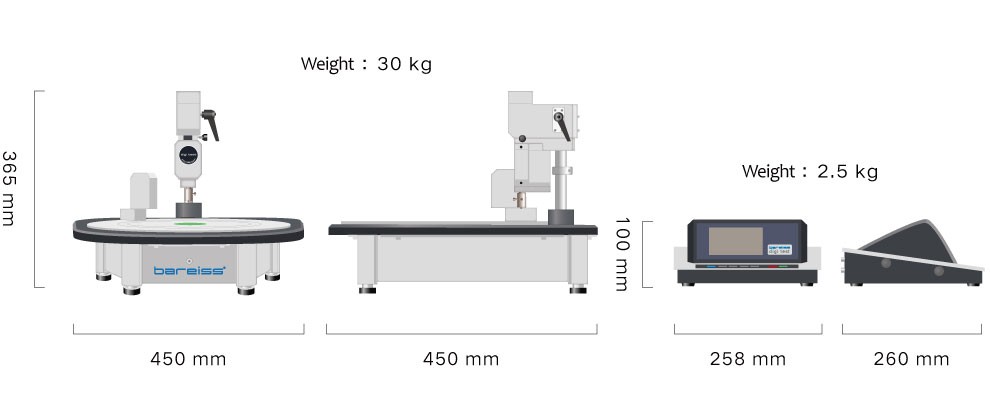

| Dimensions | 450mm x 450mm x 365mm |

| Weight | 30kg |

Thank You

Thank you for your quote request, we will contact you within 1-2 business days.

There was an error submiting the form. Please try again.