The PosiTector® SHD is an advanced Digital Durometer for hardness measurement of rubber, plastic, epoxy and more. The PosiTector® SHD features a color LCD display with user-adjustable measurement time with onscreen countdown for testing according to national and international standards. The standard model has 1000 reading memory and USB output, the advanced model adds memory for 250,000 readings in batches, live graphing, WiFi and Bluetooth output.

The PosiTector® SHD Shore Hardness Durometer can be used as a handheld instrument or placed in a test stand to reduce operator influence.

The probe can be swapped out with any other PosiTector probe allowing the device to act as several different measuring instruments including but not limited to a hardness durometer, a thermometer, a surface profiler, and a dew point meter. See related products for a more inclusive list.

Easy-To-Use

- Ready to measure—no calibration adjustment required for most applications

- Enhanced one-handed menu navigation

- Flashing display—ideal in a noisy environment

- RESET feature instantly restores factory settings

- Solvent, acid, oil, water and dust resistant - weatherproof

- Wear-resistant probe tip

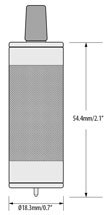

- 18.3mm (0.700") diameter footer meets all international standards

- Shock-absorbing, protective rubber holster with belt clip

- Two year warranty on gage body AND probe

- Certificate of Calibration showing traceability to NIST included (Long Form)

- Built-in temperature compensation ensures measurement accuracy

- Hi-RES mode increases displayed resolution for use on applications that require greater precision

- Conforms to national and international standards including ISO and ASTM

- Fully interchangeable probes are compatible with ALL gage bodies

- Multiple Calibration adjustment options including 1 point, 2 point, known thickness, average zero

- Selectable display languages

- Hi Contrast backlit display for bright or dark environments

- Flip display enables right-side-up viewing

- Extended cables available (up to 75 m/250 ft) for underwater or remote measuring

- Uses alkaline or rechargeable batteries (built-in charger)

- Statistics mode continually displays/updates average, standard deviation, min/max thickness and number of readings while measuring

- HiLo alarm audibly and visibly alerts when measurements exceed user-specified limits

- FAST mode - faster measurement speed for quick inspection

- USB port for fast, simple connection to a PC and to supply continuous power. USB cable included

- USB mass storage - stored readings and graphs can be accessed using universal PC/ Mac web browsers or file explorers. No software required

- Every stored measurement is date and time stamped

- Software updates via web keep your gage current

- Connects to PosiTector.net

Additional Features of the Advanced Models Include:

- NEW Storage of 250,000 readings from multiple probes in up to 1,000 batches and sub-batches

- Auto Sub-Batch—automatically create sub-batches after the required number of readings are taken

- Live graphing of measurement data

- NEW Touchscreen keyboard for quickly renaming batches, adding notes, and more

- WiFi technology wirelessly synchronizes with PosiSoft.net and downloads software updates

- Bluetooth 4.0 Technology for data transfer to a mobile device running the PosiTector App or optional portable printer. BLE API available for integration into third-party software.

- Integrate with third-party software, drones, ROVs, PLCs, and robotic devices using several industry-standard communication protocols

- Store thickness, profile, environmental, wall thickness, and hardness measurements in individual batches

All Gages Come Complete with test block, protective rubber holster with belt clip, wrist strap, 3 AAA alkaline batteries, instructions, nylon carrying case with shoulder strap, Long Form Certificate of Calibration traceable to NIST, protective lens shield, USB cable, PosiSoft Software, two (2) year warranty.

| Range | 0 - 100 |

| Accuracy | +/-1 |

| Resolution | 0.1 |

| Footer Diameter | 18.3mm (0.700") |

| Body Size | 137 x 61 x 28 mm (5.4" x 2.4" x 1.1") |

| Weight | 185 g (6.5 oz.) without batteries |

| Conforms to | ASTM D2240, ISO 868/7267/7619 and DIN 53505 |

Do your instruments require any formal training for use? Do you offer ‘demo’ models?

No. Our instruments are designed for simple operation, feature easy-to-use menus, both full and quick instruction manuals, and helpful videos. In lieu of demonstration models, we provide unlimited technical support via telephone and/or email, and a limited 30-day money back guarantee.

Is the PosiTector® SHD calibrated at the factory?

The PosiTector SHD arrives fully calibrated and ready to measure. A Long-Form Certificate of Calibration traceable to NIST or PTB is included, which documents actual readings taken by your instrument at our calibration laboratory on standards traceable to a national metrology institute. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements.

The included Test Block allows the gage operator to quickly verify correct operation and accuracy of the SHD.

What is the difference between Shore A and Shore D durometers?

PosiTector® SHD Shore Hardness Durometers measures the indentation hardness of non-metallic materials such as polymers, elastomers and rubbers. In the corrosion industry, durometers are commonly used to ensure proper curing of thick coatings and pipeline repair wraps.

The two PosiTector® SHD models look and operate identically, and vary only in the spring pressure and shape of the intender tip. This allows the two models to accurately measure different hardness ranges:

-Shore A (SHDA)- for soft to hard materials such as soft rubber, elastomers, neoprene, silicone, etc.

-Shore D (SHDD) - for medium to extra hard materials such as hard rubber, epoxies, hard plastics, PVC, acrylic, etc.

Can the PosiTector® SHD measure the hardness of metals?

No. Shore Hardness Durometers are designed to measure the indentation hardness of non-metallic materials such as polymers, elastomers and rubbers. Nearly all metals are outside the Shore Hardness scale. The manufacturer does not currently manufacture instruments for testing the hardness of metals.

Does the PosiTector® SHD include a fixture stand?

No. A PosiTector® SHD Test Stand is available as an accessory item for both SHDA and SHDD instruments.

What is the minimum thickness of material necessary to measure with the PosiTector® SHD?

According to ASTM D2240-15 “Standard Test Method for rubber Property – Durometer Hardness”, the test specimen must be at least 6.0 mm (0.24 inches) thick unless it is known that equivalent test results can be obtained with a thinner specimen. Since in-field use of a Shore durometer can concern testing the hardness of an applied coating with a measured thickness less than 6.0 mm, it is incumbent upon the operator to be aware of both the required coating thickness and its expected hardness for a particular application. Both the coating thickness and expected hardness will be specified by the coating manufacturer. Given the wide variety of coating types extant, the manufacturer has no ability to indicate a minimum coating thickness suitable for testing with our PosiTector® SHD.

Does the PosiTector® SHD measure Rockwell/Brinell/Barcol hardness?

No. The PosiTector® SHD Shore Hardness Durometer measures the Shore indentation hardness of non-metallic materials such as polymers, elastomers and rubbers. The manufacturer does not currently make other types of hardness testing instruments.

How often should the PosiTector® probe be recalibrated?

PosiTector® probes include a Certificate of Calibration with no expiry or end date. They have no shelf life, therefore the length of time in the field is not a good indicator for recalibration intervals. Many organizations with quality programs and recertification programs require annual recalibrations, and this is a good starting point for most users. The manufacturer recommends that customers establish calibration intervals based upon their own experience and work environment. Based on our product knowledge, data and customer feedback, a one year calibration interval from the date the instrument was placed in service is a good starting point.

No. Our instruments are designed for simple operation, feature easy-to-use menus, both full and quick instruction manuals, and helpful videos. In lieu of demonstration models, we provide unlimited technical support via telephone and/or email, and a limited 30-day money back guarantee.

Is the PosiTector® SHD calibrated at the factory?

The PosiTector SHD arrives fully calibrated and ready to measure. A Long-Form Certificate of Calibration traceable to NIST or PTB is included, which documents actual readings taken by your instrument at our calibration laboratory on standards traceable to a national metrology institute. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements.

The included Test Block allows the gage operator to quickly verify correct operation and accuracy of the SHD.

What is the difference between Shore A and Shore D durometers?

PosiTector® SHD Shore Hardness Durometers measures the indentation hardness of non-metallic materials such as polymers, elastomers and rubbers. In the corrosion industry, durometers are commonly used to ensure proper curing of thick coatings and pipeline repair wraps.

The two PosiTector® SHD models look and operate identically, and vary only in the spring pressure and shape of the intender tip. This allows the two models to accurately measure different hardness ranges:

-Shore A (SHDA)- for soft to hard materials such as soft rubber, elastomers, neoprene, silicone, etc.

-Shore D (SHDD) - for medium to extra hard materials such as hard rubber, epoxies, hard plastics, PVC, acrylic, etc.

Can the PosiTector® SHD measure the hardness of metals?

No. Shore Hardness Durometers are designed to measure the indentation hardness of non-metallic materials such as polymers, elastomers and rubbers. Nearly all metals are outside the Shore Hardness scale. The manufacturer does not currently manufacture instruments for testing the hardness of metals.

Does the PosiTector® SHD include a fixture stand?

No. A PosiTector® SHD Test Stand is available as an accessory item for both SHDA and SHDD instruments.

What is the minimum thickness of material necessary to measure with the PosiTector® SHD?

According to ASTM D2240-15 “Standard Test Method for rubber Property – Durometer Hardness”, the test specimen must be at least 6.0 mm (0.24 inches) thick unless it is known that equivalent test results can be obtained with a thinner specimen. Since in-field use of a Shore durometer can concern testing the hardness of an applied coating with a measured thickness less than 6.0 mm, it is incumbent upon the operator to be aware of both the required coating thickness and its expected hardness for a particular application. Both the coating thickness and expected hardness will be specified by the coating manufacturer. Given the wide variety of coating types extant, the manufacturer has no ability to indicate a minimum coating thickness suitable for testing with our PosiTector® SHD.

Does the PosiTector® SHD measure Rockwell/Brinell/Barcol hardness?

No. The PosiTector® SHD Shore Hardness Durometer measures the Shore indentation hardness of non-metallic materials such as polymers, elastomers and rubbers. The manufacturer does not currently make other types of hardness testing instruments.

How often should the PosiTector® probe be recalibrated?

PosiTector® probes include a Certificate of Calibration with no expiry or end date. They have no shelf life, therefore the length of time in the field is not a good indicator for recalibration intervals. Many organizations with quality programs and recertification programs require annual recalibrations, and this is a good starting point for most users. The manufacturer recommends that customers establish calibration intervals based upon their own experience and work environment. Based on our product knowledge, data and customer feedback, a one year calibration interval from the date the instrument was placed in service is a good starting point.

| Item | Description | Price | ||

|---|---|---|---|---|

SHDA3 | PosiTector® Durometer, Shore A with Advanced Gauge Body | $1,355.00 | ||

| Accessories | ||||

SHDSTANDA | PosiTector® Durometer Shore A Test Stand, durometer sold separately | $1,325.00 | ||

SHDSTANDD | PosiTector® Durometer Shore D Test Stand, durometer sold separately | $1,325.00 | ||

PROBE-SHDA | PosiTector® Shore A Durometer Probe Without Display - PRBSHDA | $565.00 | ||

PROBE-SHDD | PosiTector® Shore D Durometer Probe Without Display - PRBSHDD | $565.00 | ||

SHDTEST30A | Shore A-30 Test Block | $25.00 | ||

SHDTEST50A | Shore A-50 Test Block | $25.00 | ||

SHDTEST75A | Shore A-75 Test Block | $25.00 | ||

SHDTEST25D | Shore D-25 Test Block | $25.00 | ||

SHDTEST46D | Shore D-46 Test Block | $25.00 | ||

SHDTEST75D | Shore D-75 Test Block | $25.00 | ||

SHDPRBMNT | Universal Mounting Kit SHD Durometer Test Stand | $540.00 | ||

Bluetooth Printer for PosiTector Series Gauges | $340.00 | |||

PAPERBT | 10 Rolls of Paper for the Bluetooth Printer (PRINTERBT) | $20.00 | ||

Plastic Inspection Case (small) | $40.00 | |||

LENSSHIELD | Protective Lens Shields, Pack of 5 for PosiTector® 6000 Display | $10.00 | ||

USBAC | AC Power Adapter, 100-230V for PosiTector 6000 Display | $45.00 | ||

In stock

1 Week Lead Time (Estimated)

2-3 Week Lead Time (Estimated)

Lead Time Varies, Please contact us for availability.

Unavailable