The Model X-ST is available in seven capacities from 100 lb to 10,000 lb or 25 kg to 5000 kg. Accuracy is ±1% of full range. (Note: For applications requiring capacities beyond 10,000 lb or 5000 kg in tension, consider our range of dynamometers).

Proven accuracy and ruggedness sets our mechanical force gauge apart in the force measurement industry. The "D" shaped deflection beam is the heart of the X-ST. Highly engineered materials with close machining tolerances and proper heat treatment provide optimum strength and spring characteristics.

Tension Force Gauges in capacities through 2,000 lb (1000 kg) are supplied with two rod-end connectors. 5,000 and 10,000 lb (5000 kg) capacities are equipped with convenient shackles and pins.

Calibration is available in pounds, kilograms or Newtons.

NIST Traceable Calibration Certificate is included.

24-month Limited Manufacturer's Warranty

Made in the USA

Proven accuracy and ruggedness sets our mechanical force gauge apart in the force measurement industry. The "D" shaped deflection beam is the heart of the X-ST. Highly engineered materials with close machining tolerances and proper heat treatment provide optimum strength and spring characteristics.

Tension Force Gauges in capacities through 2,000 lb (1000 kg) are supplied with two rod-end connectors. 5,000 and 10,000 lb (5000 kg) capacities are equipped with convenient shackles and pins.

Calibration is available in pounds, kilograms or Newtons.

NIST Traceable Calibration Certificate is included.

24-month Limited Manufacturer's Warranty

Made in the USA

| Model | Capacity | Resolution |

|---|---|---|

| 30443-0044 | 100 lb | 1 lb |

| 30445-0034 | 250 lb | 2.5 lb |

| 30445-0018 | 500 lb | 5 lb |

| 30276-0012 | 1,000 lb | 10 lb |

| 30440-0013 | 2,000 lb | 20 lb |

| 30443-0093 | 50 kg | 0.5 kg |

| 30445-0026 | 200 kg | 2 kg |

| Capacity | Deflection |

|---|---|

| 50 - 250 lb (25 - 100 kg) | 0.019" |

| 500 lb (200 kg) | 0.016" |

| 1,000 lb (500 kg) | 0.018" |

| 2,000 lb (1,000 kg) | 0.011" |

| 5 and 10,000 lb (2 and 5,000 kg) | 0.010" |

| 25,000 b (10,000 kg) | 0.022" |

When measured across the center of top- and bottom-loading holes

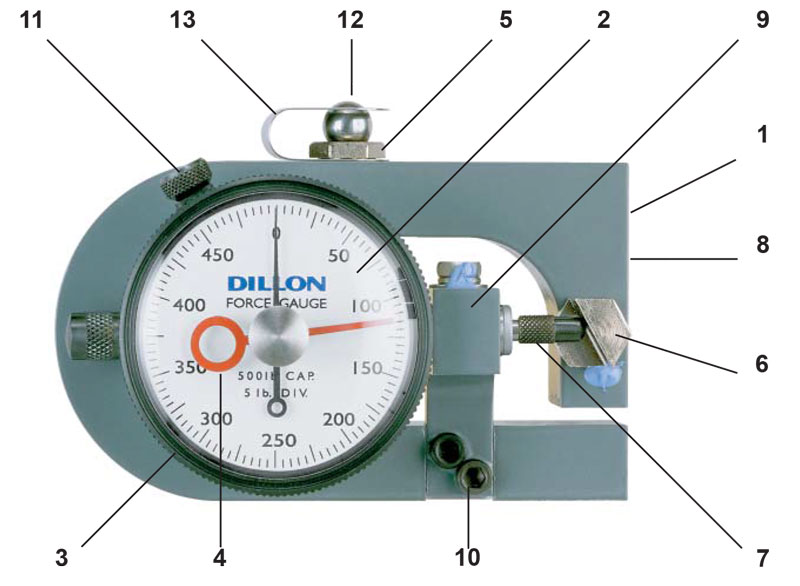

| 1. | Deflection beam |

| 2. | Dial indicator with zero at standard 12:00 position |

| 3. | Bezel |

| 4. | Maximum load pointer (optional) |

| 5. | Pressure button |

| 6. | Slanted Anvil |

| 7. | Dial indicator plunger |

| 8. | Anvil set screw |

| 9. | Mounting bracket for dial indicator |

| 10. | Screws for mounting bracket |

| 11. | Bezel-locking screw |

| 12. | Loading ball |

| 13. | Spring retainer clip |

A D-shaped deflection beam is the heart of the Dillon Force Gauge. Machined to close tolerances, beams are heat treated to develop optimum strength and spring characteristics. High-strength aluminum is used in Model X instruments through 500 lb (200 kg). Ranges above this are fabricated from aircraft-quality alloy steel.

A precision dial indicator is mounted at the null point of the deflection beam. The indicator plunger rests against a slanted anvil at the open end of the beam, as shown in the photo. Under compression loads, the two halves of the beam tend to close. Tension force causes them to move apart. This action pushes the plunger inward, as determined by the slant of the anvil. Readings produced on the dial are in direct relation to applied load. The pointer revolves 360° clockwise under compression or tension forces. Push-pull gauges read half scale (180°) clockwise in compression, and counterclockwise, 180° from center zero under tension loads.

A precision dial indicator is mounted at the null point of the deflection beam. The indicator plunger rests against a slanted anvil at the open end of the beam, as shown in the photo. Under compression loads, the two halves of the beam tend to close. Tension force causes them to move apart. This action pushes the plunger inward, as determined by the slant of the anvil. Readings produced on the dial are in direct relation to applied load. The pointer revolves 360° clockwise under compression or tension forces. Push-pull gauges read half scale (180°) clockwise in compression, and counterclockwise, 180° from center zero under tension loads.

- Shockless dial indicator for installations involving the sudden application or release of force. (Maximum pointer cannot be supplied with shockless dial indicator)

- Maximum load pointer which remains at peak load until manually reset.

- Zero position on dial may be factory positioned at 12, 3, 6, or 9 o'clock. Standard position is at 12 o'clock.

| Accuracy | ±1% |

| Operating Temperature | up to 120°F (48°C) |

| Warranty | 2 Years |

| Overload rating | Accidental overloads up to 30% of capacity can be safely sustained without injury to the dial indicator or deflection beam. All capacities feature a 5:1 design safety factor. |

| Item | Description | Price | ||

|---|---|---|---|---|

30445-0182 | X-ST Mechanical Force Guage with Tension Calibration with Maximum Hand - 100kg Capacity | $1,815.00 | ||

| Accessories | ||||

X-ST-S | Shockless dial indicator. Not available with maximum load pointer. | $120.00 | ||

In stock

1 Week Lead Time (Estimated)

2-3 Week Lead Time (Estimated)

Lead Time Varies, Please contact us for availability.

Unavailable