The Dakota MX2-DL / MVX offers a series of advanced features including A-Scan, B-Scan as well as a complete alphanumeric datalogging system with storage capacity of 100's of thousands of data values and A-scan captures. No need for software.

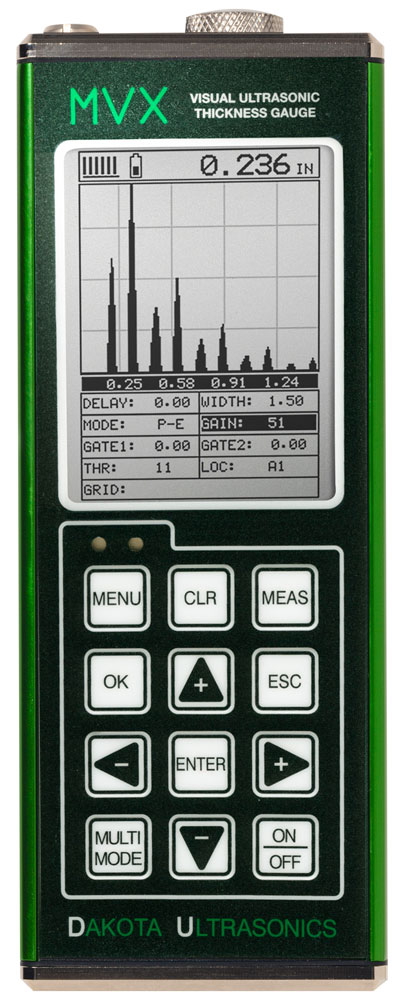

The MX2-DL / MVX features the highest resolution graphic LCD on the market and is especially engineered for optimal ease of use. It is supplied as a complete kit with all accessories in carrying case with data transfer cable and NIST-Traceable Calibration Certificate.

- The MVX is equipped with multiple viewing options to provide users with a complete set of inspection tools: (RF waveform, +/- Rectified waveform, Time based B-Scan, and Large Digits).

- The A-Scan rectified mode is commonly used for detecting flaws/pits in pulse-echo mode and measuring through paint and coatings in echo-echo mode.

- The time-based B-Scan feature of the MVX displays a cross section of the test material. It is commonly used to display the profile of the bottom surface of the test material.

- Built in hardware AGC gain control for through paint measurements in multi mode operation.

- The MVX has the ability to store 64 custom user defined setups. All factory setups can be selected, edited and saved to any setup location.

- CE Certified

- Use the visual alarm to set hi and lo limits for applications requiring specific tolerances. If the actual thickness value is above or below the limits, a red light is illuminated.

- Use the find feature to locate the detection point, while automatically adjusting the display to bring the signal into view.

- MVX also comes complete with our Windows® PC software for transferring data to and from a PC.

- Includes Flaw Inspection - Prove Up Mode, (special probe required)

- The high speed scan feature speeds up the inspection process by making 32 measurements per second. Remove transducer from the tesst material, and display the minimum measurement scanned.

- Includes NIST-Traceable Calibration Certificate

The MVX is supplied as a complete kit with the gauge, 4 oz. bottle of coupling fluid, 2 AA batteries, NIST-Traceable Calibration Certificate, data transfer software, serial output cable and Operating Instruction Manual - all in a foam-fitted carrying case.

| Range in Steel*: | Pulse-Echo Mode: Pit and Flaw detection measures from 0.63 to 254 millimeters (0.025 - 9.999inches) Echo-Echo Mode: Thru Paint & coatings measures from 2.54 to 102 mm (0.1 - 4.0 inches). Range will vary +/- depending on the thickness of coating. |

| Resolution: | .001 inches (0.01mm) |

| Velocity Range: | .0492 to .3936 in./ms 1250 to 9999 meters/sec |

| Units: | English & Metric |

| Measurement Modes: | - Pulse-Echo (flaws, pits) - Echo-Echo (thru-paint) |

| Transducer Types: | Dual Element (1 to 10 MHz). |

| Memory: | 16 megabit non-volatile ram |

| Memory capacity: | 12,000 pages with 1 reading and waveform per page |

| Power Source: | Three 1.5V alkaline or 1.2V NiCad AA cells |

| Battery Life: | Typically operates for 150 hours on alkaline and 100 hours on NiCad |

| Auto Power off: | if idle 5 min |

| Display: | 1/8 in. VGA grayscale display 62 x 45.7mm |

| Keyboard: | Membrane switch with twelve tactile keys |

| Case: | Extruded aluminum body with nickel-plated aluminum end caps (gasket sealed). |

| Operating Temperature: | -14° to 140°F (-10° to 60°C) |

| Weigth, net: | 383 grams |

| Dimensions: | 63.5 W x 165 H x 31.5 D mm |

| Warranty: | 2 year limited on gauge, 90 days on probe |

| Certification: | CE Approved, Factory calibration traceable to national standards |

| A-Scan Scan Mode | B-Scan Mode | Large Digits |

|

|

|

| The A-Scan rectified mode is the preferred display view for flaw and pit detection applications and measuring through paint and coatings in the echo-echo mode. | The B-Scan view displays a time-based cross section of the test material. It is commonly used to display the profile of the blind or underside of a pipe or tank. | The Large Digits view provides a basic digital thickness gauge look and feel. The large display makes it easy for the operator to monitor the thickness readings. |

| Item | Description | Price | ||

|---|---|---|---|---|

MX2-DL / MVX Ultrasonic Thickness Gauge with T-102-2700 probe - Z-149-0004 Z-160-0005 | $2,850.00 | |||

| Accessories | ||||

1/4" diameter, 5.0 MHz Hi-Damped transducer for thru paint measurement, Side In, Potted | $360.00 | |||

1/2" diameter, 1.00 MHz dual element transducer, Side In, Potted | $330.00 | |||

1/2" diameter, 2.25 MHz dual element transducer, Side In, Potted | $330.00 | |||

1/2" diameter 5.0 MHz dual element transducer Hi-Temp (650 F/344 C), Side in, Microdot | $405.00 | |||

3/16" diameter, 5.0 MHz dual element transducer, Side In, Potted | $320.00 | |||

1/4" diameter, 2.25 MHz, dual element transducer, Side In, Potted | $320.00 | |||

1/4" diameter, 7.5 MHz, dual element transducer, Side in, Potted | $355.00 | |||

Protective Holder for Long Body UT Gauges, F-149-0001 | $85.00 | |||

V-Block Transducer Holder (For 3/16" & 1/4" Transducers only), F-000-7001 | $170.00 | |||

SoundSafe Coupling Fluid - 12 oz / 354 ml - NSN: 6635-01-553-0559 | $30.00 | |||

N-104-0021 | 4 ft Cable, Dual Lemo-to-Single Microdot | $115.00 | ||

N-110-0020 | 10' Single Lemo to Microdot Cable | $90.00 | ||

QCR5050 | 1/2"-5MHz Hi-Res Quick-change Single Element Contact Transducer for use in flaw mode | $260.00 | ||

QW5045-DNU | Use p/n X-004-0044 | $0.00 | ||

QW5060-DNU | Use p/n x-004-0045 | $0.00 | ||

QW5070-DNU | Use p/n X-004-0046 | $0.00 | ||

1/4" diameter, 5.0 MHz dual element transducer Hi-Temp (900 F/500 C) Top in, Microdot | $470.00 | |||

Protective Rubber Boot for Tall Format Ultrasonic Thickness Gauges | $115.00 | |||

In stock

1 Week Lead Time (Estimated)

2-3 Week Lead Time (Estimated)

Lead Time Varies, Please contact us for availability.

Unavailable